Environmental Engineering Reference

In-Depth Information

15.3 MODEL SYSTEMS TO STUDY SIZE EFFECTS

IN ELECTROCATALYSIS

In PEMFCs, the membrane electrode assembly (MEA, Fig. 15.2a) is a multilayer

sandwich composed of catalytic layers (CLs) where electrochemical reactions

take place, gas-diffusion media providing access of gases to the CLs, and a proton

exchange membrane (PEM) such as Nafion

w

. The CL is a multiphase multicomponent

medium comprising:

†

a catalyst, usually nanometer-sized noble metal particles supported on porous

carbon materials, accelerating the rates of electrochemical reactions

†

an ionomer, allowing flow of protons through the MEA

†

gas- and liquid-filled pores, providing access of the reagents to and the products

from the catalyst surface

In practice, the catalytic layers are prepared by brushing or spraying “catalyst ink”

(a suspension of the catalyst particles in water and/or an organic solvent with addition

of ionomer) either onto diffusion media (carbon paper or carbon cloth, also referred to

as substrates), resulting in so-called catalyst-coated substrates (CCS), or directly onto

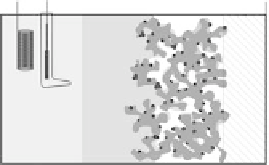

Figure 15.2 Schematic representation of different electrochemical cell types used in studies of

electrocatalytic reactions: (a) proton exchange membrane single cell, comprising a membrane

electrode assembly; (b) electrochemical cell with a gas diffusion electrode; (c) electrochemical

cell with a thin-layer working electrode; (d) electrochemical cell with a model nonporous elec-

trode. CE, counter-electrode; RE, reference electrode; WE, working electrode.

Search WWH ::

Custom Search