Environmental Engineering Reference

In-Depth Information

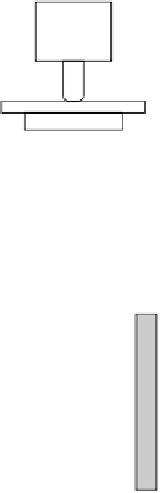

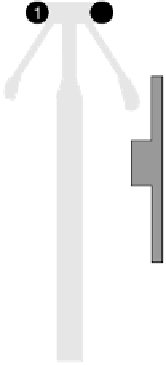

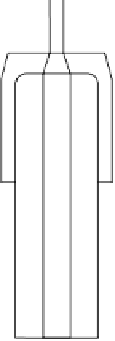

Figure 14.1

Scheme of the electrochemical flow cell used in the UHV-STM/EC transfer

system.

facilities for the reversible sample transfer between UHV and electrochemical cell.

The UHV system contained two metal evaporators for Pt and Ru evaporation, a cylind-

rical mirror analyzer (Physical Instruments) for Auger electron spectroscopy (AES),

and a quadrupole mass spectrometer (Balzers QMS 112) for residual gas analysis.

The single-crystal sample, which was shaped as a flat “hat,” was mounted onto a tan-

talum or molybdenum sample holder with an outer diameter of 18 mm (see Fig. 14.1),

which in turn was held in a precision sample manipulator. Sample heating was poss-

ible by radiation heating from a filament behind the sample or by electron bombard-

ment, accelerating electrons from the filament to the sample. The latter allowed to

flash anneal the sample to temperatures of up to 1900K (heating rate

100 K s

21

).

The temperature was measured by an infrared pyrometer (Impac Infratherm IGA

140). For STM measurements, the sample was transferred from the manipulator to

the STM by two wobble sticks.

14.2.2 Sample Preparation

The Ru(0001) surface was prepared by cycles of Ar

þ

ion bombardment (sputtering)

and annealing to temperatures .1100K, followed by oxygen adsorption/desorption

cycles and final annealing to about 1750K to remove residual adsorbed oxygen

[Buatier de Mongeot et al., 1998; Diemant et al., 2003]. After this treatment, the

surface is characterized by atomically smooth terraces of 100 - 200 nm width separated

by monolayer steps (see also Fig. 14.5a). Surface contamination was below the

Search WWH ::

Custom Search