Environmental Engineering Reference

In-Depth Information

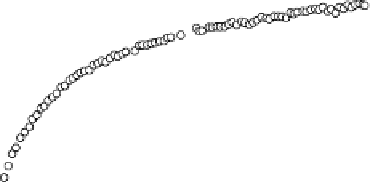

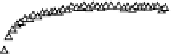

Figure 11.1 Kinetics of adsorption of CO at a Pt catalyst from a 0.01 M methanol solution

at different potentials. (a) Pt black catalyst, with Pt loading 0.8 mg cm

22

. (b) Pt

0.5

Ru

0.5

black

catalyst, with catalyst loading 0.8 mg cm

22

(0.1 M H

2

SO

4

, T ¼ 298K).

catalyst structure [Dubau et al., 2003b; Waszczuk et al., 2001b; Brankovic et al.,

2002a, b]; optimization of the Pt/Ru atomic ratio [Kabbabi et al., 1998; Iwasita

et al., 2000; Dinh et al., 2000; Watanabe et al., 1987; Gasteiger et al., 1994;

Ianniello et al., 1994]; and the use of a third alloying metal [Lima et al., 2001]. A cru-

cial aspect is the method used to prepare nanostructured catalysts, leading to different

catalyst structures and compositions, in a controlled way by varying the experimental

conditions only slightly. The colloidal route for catalyst preparation derived from the

method developed by B ¨ nnemann and co-workers [B ¨ nnemann et al., 1991, 1996] is

very convenient for obtaining Pt-Ru compounds with controlled size, composition,

and structure [Dubau et al., 2003a, b; Dubau, 2002]. Catalytic powders can be

obtained in the following ways: (i) Pt/C and Ru/C, from deposition of a Pt colloid

or a Ru colloid solution on carbon; (ii) Pt-Ru/C, from deposition of alloyed Pt-Ru

Search WWH ::

Custom Search