Agriculture Reference

In-Depth Information

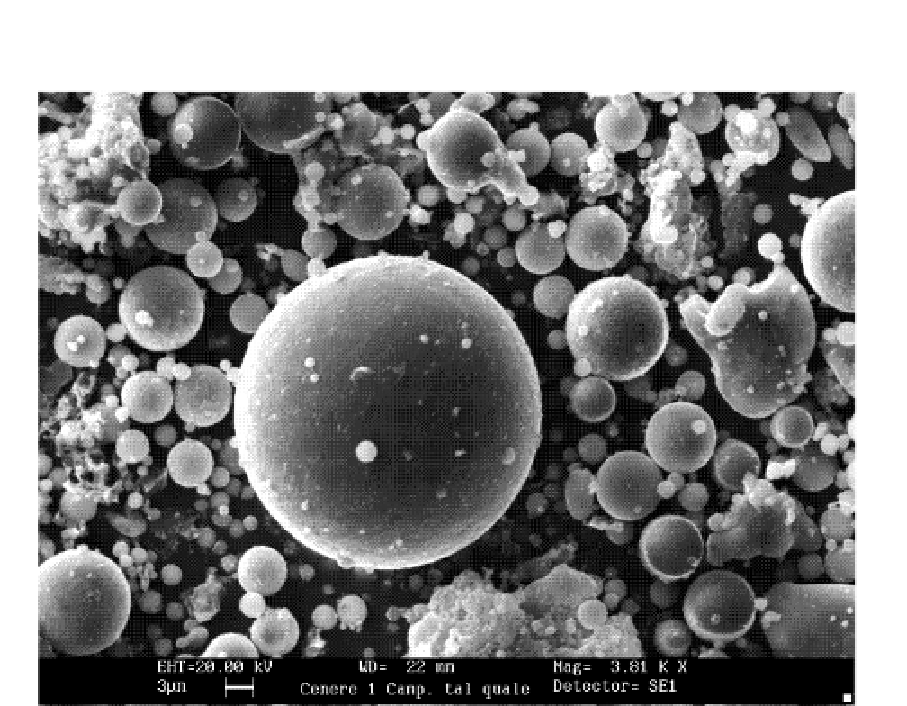

The morphological study confirms the results on particle distribution and shows that the

typical aspect of globules is close to an ideal sphere in shape (Fig. 2).

Fig. 2. SEM images of typical fly ash shape.

The amount of unburned carbon was estimated to be about 6% derived by comparing the

results obtained through the thermogravimetric analysis carried out in different

environmental atmospheres (Fig. 3). LOI value was calculated by using both flow of inert

and oxidising gas (the latter is composed of air and CO2, 1:1). When fly ashes were heated in

inert gas, the loss of weight due to the water released from hydrated lime can be estimated

because, obviously, in an inert environment, carbon oxidation does not take place. The

utilization of an oxidising atmosphere permits the determination of the loss of ignition due

to carbon oxidation, plus a water loss from hydrated lime. The first reaction takes place

within the range 500-800°C, as showed by a large peak in that range. A comparison between

the two values permits the calculation of the amount of unburned carbon more precisely.

The XRD patterns in Figure 4 show that the main crystalline phases are mullite and quartz.

The broad hump in the region between 10 and 25 °2θ indicates the abundant presence of

glassy phase due to the rapid cooling of fly ash at high temperatures. The weight fractions of

mineral and amorphous phases are shown in a diagram (Fig. 5).

The high percentage of amorphous material and the presence of hematite/goethite on trace

give evidence of the application of these fly ashes in cement products and zeolite synthesis.

The chemical composition for major elements, the SiO

2

/Al

2

O

3

ratio ranging from 1.7 to 2.0,

and the low concentration of toxic elements represent important factors for the application

of these materials as well.