Agriculture Reference

In-Depth Information

Four coal fly ashes resulting from the combustion of four different coal materials were

supplied by ENEL thermoelectric powder plants in Brindisi and Venice - Italy.

The particle size distribution was studied by laser granulometry using the principle of laser

diffraction. The fly ash samples were also analysed by SEM-EDS. This analysis provided

detailed imaging information about the morphology and surface texture of each single

particle, as well as the elemental composition of samples.

The chemical abundance of major elements was determined by X-ray fluorescence (XRF)

(Franzini et al., 1075; Leoni & Saitta, 1976) and the concentrations of potentially harmful

trace were measured by inductively couple plasma spectrometry (ICP-MS) after total acid

dissolution treatment of the samples.

The mineral composition of fly ashes was determined by XRD and the quantitative XRD

analysis of crystalline phases was carried out by using the reference intensity ratio (RIR)

method (Chung, 1974a; 1974b; 1975) combined with the “method of known additions”

(Snyder & Bish; 1989). The amount of amorphous materials was calculated through the

subtraction of crystalline components. Finally, thermogravimetric analyses were carried out

in order to find out the concentration of unburned carbon.

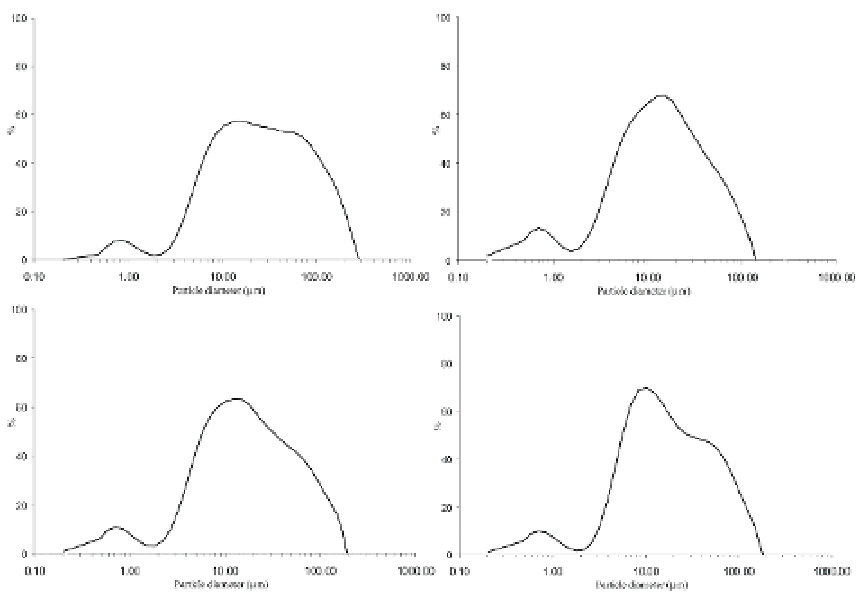

The complete resulting distribution of the particles of fly ash samples are shown in Figure 1.

Two samples are mainly made of particles whose diameters range from 5 to 50 µm, the other

fly ashes show two main set ranges from 5 to 30 µm and from 70 to 90 µm. All the samples

analyzed show an ultra fine fraction ranging from 0.5 to 2.0 µm. This slight variation in size

distribution could be due to similar methods for collecting fly ash used in the different

power stations.

Fig. 1. Particle size distribution of the fly ashes samples.