Information Technology Reference

In-Depth Information

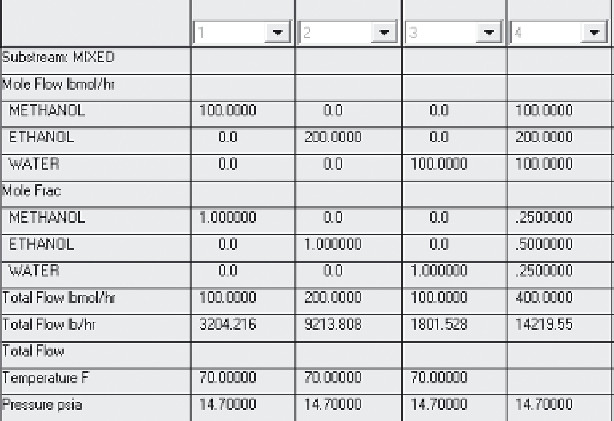

Figure 5.17

Results of Mixer5t.

5.7 WORKSHOPS

Workshop 5.1

Copy the file four3n.bkp, which will be the basis for using Aspen

Plus's Sensitivity Studies capability to determine the effect of the decanter's perfor-

mance with regard to the fraction of cyclohexane leaving the decanter in its aqueous

product, stream C. For the base case this specification is 0.02. The Sensitivity Studies

should vary this value between 0.01 and 0.10 in increments of 0.01. Select as tear

streams C and F. Make a reasonable estimate of the componential flows and solve the

flowsheet using the Newton convergence option. This becomes the base case solution.

This file is to be modified using the Sensitivity function. Select the following as the

dependent variables:

1. The total flow of stream G,

the cyclohexane-rich distillate recycled to the

decanter. Call it FLOWG.

2. The flow of cyclohexane in stream G. Call it FLOWGC.

Plot the results. If the pipeline in which G is to flow is limited to 300 lb/hr, what is

the fraction of the cyclohexane entering the decanter that leaves in stream C?

Workshop 5.2

Using Workshop 5.1 as a basis for solving Workshop 5.1 by means

of the Design Specification capability of Aspen Plus, delete the Sensitivity function and

replace it with Design-Spec. Vary the decanter performance with regard to cyclohexane

in stream C and use it as brackets for the iterations 0.01 and 0.10. Set up the design

specification such that the total flow rate of stream G is 300 lb/hr with a tolerance of

0.1 lb/hr. What is the fraction of the cyclohexane entering the decanter that leaves in

stream C?