Information Technology Reference

In-Depth Information

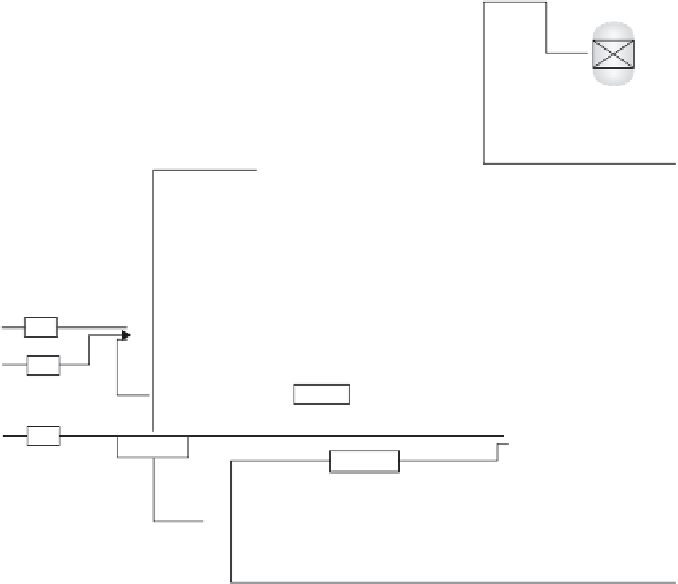

ETAZL

ETAZH

B1

B2

CRUDETOH

ETH

TOLSTILL

ETAQ

TOL

SOLVNTS

DECANT

CRUDTOL

AQTOL

CRUDSTL

FD1

FD2

RSLVNT

STMSTRIP

FD3

CRSOLIDS

AQSLVNT

WATER

FILTER

SOLIDS

Figure 4.6

Distillation train.

composition is to be 99% water. All of the toluene fed ends up in the stream ETAQ.

The stream ETAZH feeds the column ESTILLLO. This column produces the relatively

pure product ETH, which is to contain 99 mol % ethanol, and the product ETAZL,

which is to contain 82 mol % ethanol. The stream ETAZL is recycled to column

ESTILLHI.

A steam stripper (STMSTRIP) is provided to remove solvents from the aqueous

products of the process, ETAQ and AQSLVNT. The stream FD3 consists of 50 lb/hr

of 30-psig steam that is used as the energy source for the stripping the solvents. The

stripper produces the stream RSLVNT, which contains the stripped solvents and is

recycled to the column CRUDSTL. The stream WATER is discharged to the envi-

ronment. The performance characteristics of the stripper are as follows: 0.5% of the

ethanol fed, 90% of the water fed, and 0.01% of the toluene fed end up in the stream

WATER.

a. There is no component SOLIDS. Devise a method that will permit this component

to be used in the simulation.

b. To calculate the material balance for the complete process flow sheet, it may

be advisable to break up the process into manageable segments that are to be

combined when the complete material balance is solved. Select the segments and

solve each using an estimate for the required feeds when necessary.