Information Technology Reference

In-Depth Information

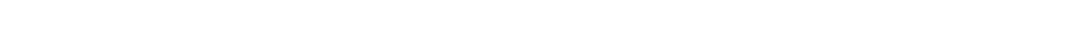

ETAZL

B2

B1

ETAZH

CRUDETOH

ETH

TOL

Figure 14.3

Homogeneous azeotropic distillation flowsheet.

14.2 HOMOGENEOUS AZEOTROPIC DISTILLATION

Figure 14.3 shows an example of the configuration of two distillation columns set up for

homogeneous azeotropic distillation. The intent of the separation is to produce nearly

pure ethanol from a mixture of ethanol and toluene whose composition is below the

azeotrope's composition. The arrangement of the two columns takes advantage of the

difference in azeotrope composition at different pressures. To facilitate the following

example, Aspen Plus's stored Wilson equation binary parameters, which are shown

in Table 14.1 are used to estimate the composition of the azeotrope as a function of

pressure. If these were to be used for an industrial application, the results would need

to be checked against experimental data.

The basic idea of the separation is explained with reference to Figure 14.3. A

simple material balance shows that the larger the pressure differential between the two

azeotropes, the smaller the recycle flow ETAZL. For illustration purposes, the higher-

pressure column, B1, is selected to operate at 760 mmHg and the lower-pressure

column, B2, at 50 mmHg. The stream ETAZH's composition is approximately 0.815

mole fraction ethanol and feeds the column B2. The stream ETAZL's composition

is approximately 0.685 mole fraction ethanol and is a second feed to column B1.

The bottoms product of column B2 is nearly pure ethanol, and the bottoms product

of column B1 is nearly pure toluene. Other pressures can surely be selected with an

analysis of the trade-off between recycle flow and associated operating costs against

the costs associated with purchase and installation of the columns. An initial estimate

of the design of the two columns can easily be done using the McCabe -Thiele method

on both columns. The low-pressure column can be analyzed with the toluene as the

more volatile component.

When such a design is undertaken, the following procedure is recommended:

1. Locate a source of experimental data and fit it to an activity coefficient equation.

2. Determine the azeotrope composition as a function of pressure.

TABLE 14.1 Ethanol-Toluene Azeotrope at Various Pressures

Pressure (mmHg)

50

100

400

760

1420

Mole fraction ethanol

0.685

0.715

0.77

0.815

0.85