Information Technology Reference

In-Depth Information

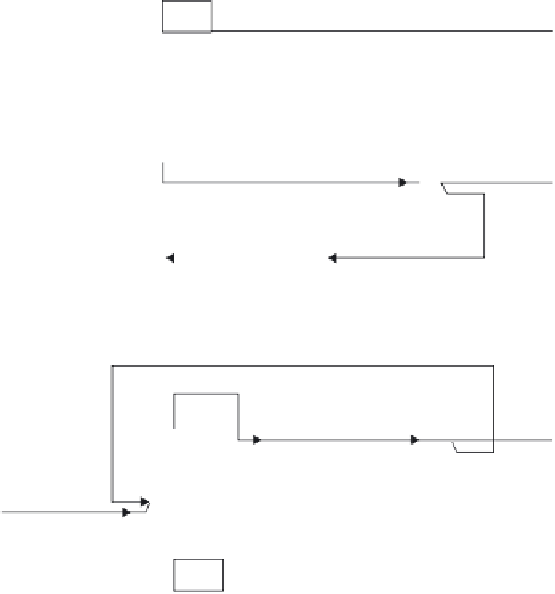

A method that has much greater potential is applicable when two columns operate

at temperatures such that the overhead temperature of one column is at a higher tem-

perature than the bottoms of the other, and the net reboiler duty of the first is on the

same order of magnitude as the condenser duty of the other. The procedure is to use

one side of a single heat exchanger as the reboiler of column 1 and the other side as

the condenser for column 2. This is illustrated in Figure 14.1. In this example a small

heat exchanger is used to make up for the insufficiency of the net heat flow between

heaters 1 and 2.

One may note that both columns' configurations have changed considerably. The

first column is reconfigured as a refluxed stripper, and only one degree of freedom,

such as the reflux ratio, is available. The bottoms product of the column is split in a

ratio that is equivalent to the second degree of freedom if the column were not energy

integrated: for example, the value of the vapor/distillate ratio, or the flow leaving the

splitter.

The second column is configured as a reboiled absorber, which also has only one

degree of freedom. This could be the boil-up ratio or the bottoms product rate. The

reboiler - condenser is modeled as a pair of heaters with a heat stream flowing from

the condenser half to the reboiler half. The overhead splitter returns reflux after the

overhead flow is condensed by the reboiler - condenser heat exchanger.

D1

DIST1

FD1

6

3

B1

SP1

5

4

HT3

HT1

Q1

9

7

D2

8

HT2

SP2

DIST2

FD2

B2

Figure 14.1

Shared reboiler - condenser flowsheet.