Information Technology Reference

In-Depth Information

4

B3

6

3

B2

FLASH

1

5

2

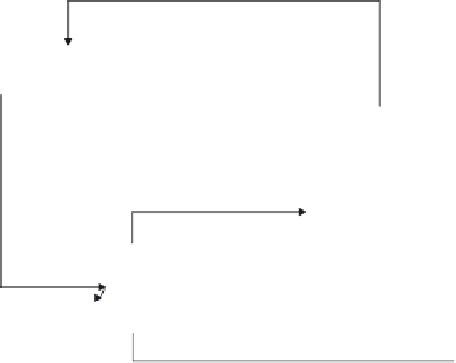

Figure 13.6

Workshop 13.2a process.

TABLE 13.1 Process Feed

Component

Flow Rate (lbmol/hr)

Propane, C3

10

n

-Butane, NC4

20

n

-Pentane, NC5

20

n

-Hexane, NC6

10

Cyclohexane, CC6

40

reflux ratio is 1.0 and the distillate/feed ratio is 0.5. The overhead product is saturated

vapor at a pressure of 50 psi, and the column bottoms pressure is 51 psi. This model

should not incorporate optimization. The feed to the process is a saturated liquid at

250 psi and its composition is given in Table 13.1.

Workshop 13.2b

Develop an optimization, maximizing profitability, of the flow-

sheet above by varying the flash pressure between 150 and 250 psi. The objective

function needs to be coded in Fortran and will incorporate the following terms:

Stream 5

n

-hexane value: $0.1/lbmole

Stream 5 cyclohexane value: $0.20/mole

Coolant cost: $1

.

0

×

10

−

6

/Btu

Heating media cost: $1

.

0

×

10

−

7

/Btu

Net work cost: $0.020/hp

Workshop 13.2c

Develop an optimization of the flowsheet in three dependent vari-

ables. In addition to flash pressure, the column distillate/feed ratio varies between 0.4

and 0.7. The internal reflux ratio varies between 0.4 and 0.7 using the same objective

function as above.