Information Technology Reference

In-Depth Information

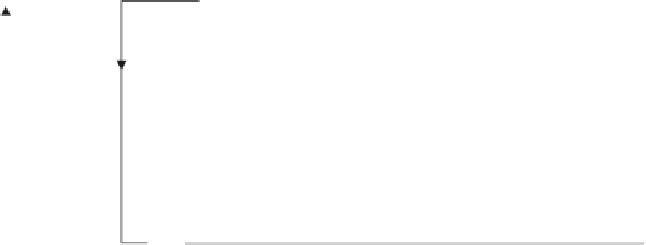

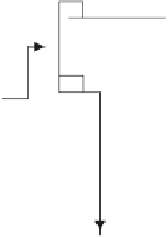

PFV

GGIN

C5M

CHILL

MIX1

DIST

FEED

CHIN

PFVO

SF

PFIN

GGHX

PF

DFD

PFL

SFL

MIX2

PUMP

SFVO

DBOT

C5R

FG

ACL

GLIN

ACLIN

C5P

DVDR

GLHX

FGAS

Figure 12.12

Process for production of natural gas.

TABLE 12.3 Component List

ID

Formula

Databank Name

Lb-mol/hr

N2

N

2

Nitrogen

52.0

CO2

CO

2

Carbon dioxide

89.12

C1

CH

4

Methane

6033.50

C2

C

2

H

6

Ethane

297.08

C3

C

3

H

8

Propane

141.62

IC4

3

(

CH

3

)

CH

Isobutane

31.84

NC4

2

(

CH

3

)

2

(

CH

2

)

n

-Butane

45.11

IC5

(

2CH

3

)

CHCH

2

CH

3

2-Methylbutane

17.60

NC5

CH

3

·

3

(

CH

2

)

CH

3

n

-Pentane

14.90

NC6

CH

3

4

·

(

CH

2

)

CH

3

n

-Hexane

19.24

Hot-side heater

: outlet at 225 psi.

Primary flash

: adiabatic at 160 psi.

Secondary flash

: adiabatic at 100 psi.

Pump

: outlet at 260 psi.

Distillation column

: use DSTWU with NC4 and IC5 as the light and heavy key

components, respectively; 99% of the light key is to be in the distillate and 99%

of the heavy key is to be in the bottoms of the column. A partial condenser is

required. The top of the column is at 240 psi and the bottom at 255 psi.

Recycle splitter

: 20% of the column bottoms are to be returned to the process.

Air cooler

: outlet at 100

◦

F and 250 psi.

Gas/liquid heat exchanger

: modeled as two heaters with a heat stream used to pass

heat between them.

Hot-side heater

:outletat80

◦

F and 237.7 psi.

Cold-side heater

: outlet at 100 psi.

A partial setup for this flowsheet exists at Workshops/Twelve-2. It is complete

except for implementation of the specifications for the gas/gas heat exchanger.