Information Technology Reference

In-Depth Information

actuality it is necessary merely to provide 560

◦

C as the set point to heaters B and D.

This is implemented at Example Twelve-4b.

12.9 MISCELLANEOUS CONSIDERATIONS

Pumps are not used at this level of development. It is understood that the use of a mostly

constant 14.7 psi pressure in this flowsheet is technically incorrect but introduces only a

small error. The feed to the distillation column was changed to 18 psi to accommodate

the column's internal pressure. The actual size and location of the equipment has not

been defined since the physical layout there has not yet been developed; therefore,

pump selection cannot proceed since the actual service is unknown. For example, the

distillation column has 60 theoretical stages, and if the efficiency is 100% and the tray

spacing is 2 ft, the column is at least 120 ft tall (a 12-story building). If the site is in

a windy area, this column may be built as two 60-ft columns with pumps in between.

Similarly, the type of equipment used for heating some streams to high temperatures

and cooling off others is unknown; thus, detailed design will be carried out by others.

The amount of water used to control the formation of by-products is unknown. The

reaction kinetics is unknown, and therefore at this point in the flowsheet development,

a reaction conversion of 35% is used. Scale-up would be from laboratory data.

12.10 WORKSHOPS

Workshop 12.1

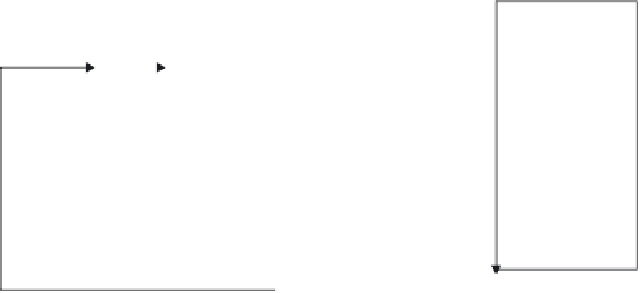

Figure 12.11 shows a section of a process for converting toluene

to benzene in a hydroalkylation reactor. The main reaction is

C

7

H

8

+

H

2

→

C

6

H

6

+

CH

4

FEED

MIX1

RECYCLE

1

GAS-RECY

VAP

6

6H

FLSH

MIX2

HX

HEATER

2

4

LIQ

3

FURNACE

REACTOR

QUENCH

PUMPED

PROD

PUMP

SPLIT

SPLIT

Figure 12.11

Process for production of benzene.