Information Technology Reference

In-Depth Information

which corresponds to about 1% water in the reactor feed. The process description did

not indicate what quantity of water is required in the reactor. Thus, 40 lbmol of water

per 100 lbmol of feed is not suitable with the process description given.

12.6 ANALYZING THE RIGOROUS DISTILLATION

The distillation feed from Example 12.2 using a 3-lbmol/hr water feed was employed

for the preliminary calculations in preparation for designing and then simulating the

column. The feed with appropriate column specifications was employed with a DSTWU

block to obtain an estimate of the number of stages, feed stage location, and reflux

ratio required. These results may be found at Examples/ExampleTwelve-3a. The results

were used to explore the design parameters of the column with several RadFrac

runs. The results of these runs culminated in a Sensitivity study with Radfrac at

Examples/ExampleTwelve-3b. The desired styrene product composition was about 0.98

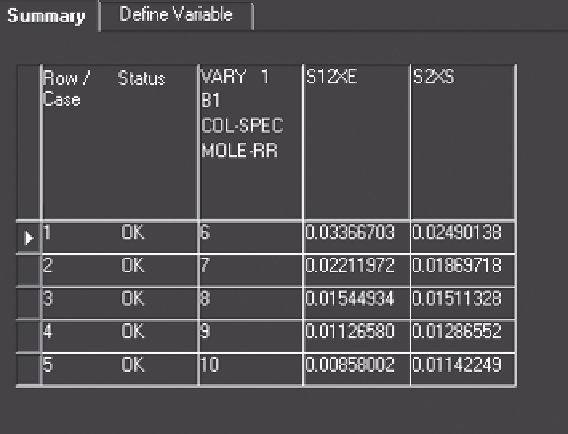

mole fraction. Figure 12.6 shows the effect of reflux ratio on the two product compo-

sitions. Here S12XE and S2XS are the mole fractions of ethylbenzene in stream 12

and styrene in stream 2, respectively. The column operates with 60 total stages, feed

on stage 30, and a distillate rate of 183 lbmol/hr. The external reflux ratio required is

about 9. Note that there is a slight amount of hydrogen in the feed; therefore, the use

of a partial condenser is imperative.

12.7 INTEGRATING THE RIGOROUS DISTILLATION

INTO THE FLOWSHEET

Introducing the converged rigorous distillation results of ExampleTwelve-3b into the

converged flowsheet of ExampleTwelve-2 with the sensitivity study removed produces

Example Twelve-4a. This example does not converge and produces several errors,

Figure 12.6

Effect of reflux ratio on product composition.