Information Technology Reference

In-Depth Information

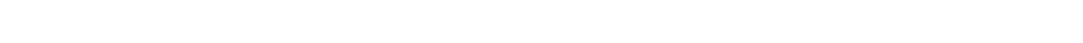

Figure 11.21

NQ curves specifications.

some of which are shown in Figure 11.22, are generated. The various reasons for the

errors include limitations at the bounds of perturbed variables. In this case the optimal

feed location and number of stages required were determined correctly from DSTWU

and are given in the base case solution. This will usually not occur unless the species

involved form relatively ideal mixtures.

Aspen Plus's RadFrac block provides many detail design functions, which are acces-

sible through the Tray and Packing Sizing and Rating folders under the RadFrac block.

These functions are based on vendor-provided information or well-known methods

described in the literature. Details of the calculations, correlations, and so on, are

given in Aspen Plus's Help documentation, Appendix A. An example of the tray design

input is given in Figure 11.23. Note that five different tray types are available. In this

example the sizing function was used for three sections of the column: enriching, feed,

and stripping. Results are shown at Examples/Example3b. When using RadFrac for

rating or simulation, the design specifications should be removed and operating spec-

ifications such as reflux ratio and distillate rate should be used. Additionally, the tray

or packing design specifications should be removed and replaced with the equivalent

tray and packing rating functions. An example of such an implementation is shown at

Examples/Example3c. Figure 11.24 shows an example of the packing input.