Environmental Engineering Reference

In-Depth Information

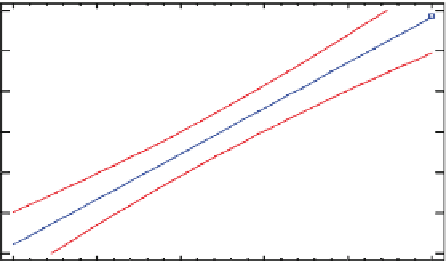

0.3

y = 0.2245x -

0.8571

0.1

-0.1

-0.3

-0.5

-0.7

-0.9

0

1

2

3

4

5

Fig. 3

Kinetic plot of Ln (C

MeOH/

a C

TG

) vs. time for the second order kinetics transesterification

reaction

[ ][ ]

−=

r

0.2245

TG MeOH

·

(mol·L ·min

−

1

−

1

)

TG

Exhaust Emissions and Fuel Consumption

The fossil diesel was mixed with the waste olive oil biodiesel, and blends contain-

ing 5% vol biodiesel were prepared. Also, samples were prepared that contained

5% vol of ethanol to compare the performance of BE-diesel fuel with fossil diesel

and biodiesel-fossil diesel blends. The results of these tests are summarized in

Tables

2

through

4

.

The effect of oxygenated fuels blends on NO

x

emissions is complex and not

conclusive. Cetane number, fuel density and aromatic fuel composition can influ-

ence NO

x

emissions. Many studies indicate that oxygenated fuel blends could cause

slight increases in NO

x

emissions

[17]

. However, in our work the reduction of NO

x

exhaust emissions was significant when using blends of fossil diesel and waste

olive oil biodiesel (−11.7%), and in good agreement with previous results

[13]

. It was

very interesting with ternary blends of BE-diesel (−32.7%) although previous

Table 2

NO

x

Exhaust emissions reduction (%)

Sample

Base fuel

Base fuel + 5% waste olive oil biodiesel

Diesel

0

−11.7

Diesel + 5% vol ethanol

−15.3

−32.7

Table 3

Particulate matter (PM) exhaust emissions reduction (%)

Sample

Base fuel

Base fuel + 5% waste olive oil biodiesel

Diesel

0

−6.1

Diesel + 5% vol ethanol

−13.1

+2.0