Environmental Engineering Reference

In-Depth Information

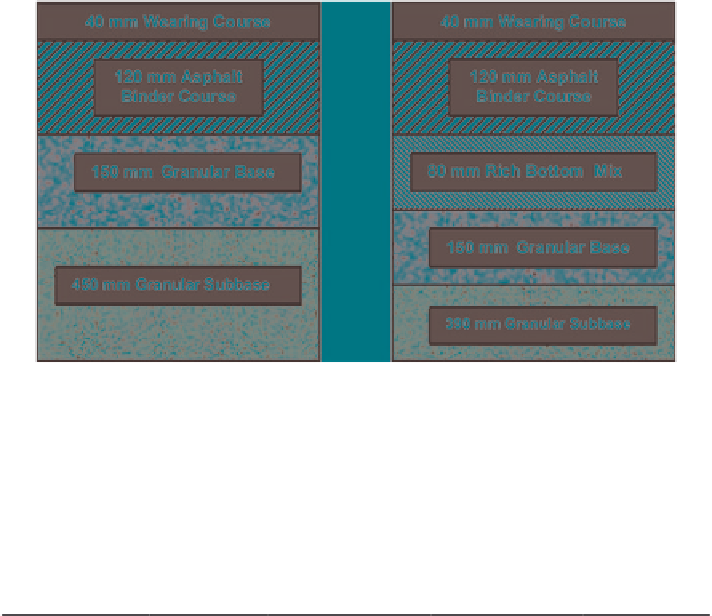

Fig. 3

Comparison of conventional pavement structure (

left

) and perpetual pavement (

right

)

Table 1

Life cycle cost comparison

Construction

cost (million

Can$)

Maintenance and

rehabilitation

(million Can$)

Total cost

(present worth

million Can$)

User delay cost

(million Can$)

Conventional

12.4

4.5

1.3

18.2

Perpetual

13.7

2.3

0.5

16.5

life cycle cost is lower (Table

1

). The user-cost estimates include user delay costs

only (i.e. delay costs and queuing costs) and not vehicle-operating costs.

Reduced Environmental Impacts

To quantify the environmental benefit of perpetual pavement over a traditional

pavement on the RHVP, the Pavement Life-cycle Assessment Tool for Environmental

and Economic Effects (PaLATE) software was used. The program was developed

by Dr. Arpad Horvath from the University of California, Berkeley as a decision-

making tool used to evaluate road construction in terms of life-cycle costing and

environmental impact

[8]

. PaLATE does not take into account vehicle emissions

during the service life. Both, perpetual and traditional pavement designs were com-

pared during the initial construction and maintenance and rehabilitation stages. The

environmental impact includes energy consumption, CO2, NOx, PM10 and SO2

emissions. The results are summarized in Table

2

.