Environmental Engineering Reference

In-Depth Information

conc 1

conc 2

conc 3

100%

80%

60%

40%

20%

0%

Cd

Cr

Cs

Cu

Mo

Ni

Pb

Sn

V n

-20%

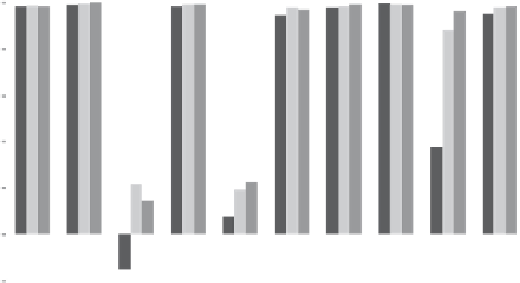

Fig. 2

Removal capacity of old furnace sludge at pH ~9 for metals in different concentrations in

real leachate spiked with multi metals and stirred in beakers (24 h)

Table 2

Sorption capacity for metals in solutions at different pH with high initial concentrations

and furnace sludge as sorbent

Sorption capacity mg/g

Furnace sludge

Old

Metals

C

0

mg/L

pH 5.6

pH 7.0

pH ~9

pH ~9

Maximum capacity

a

mg/g

Cu

21.6

1.7

4.1

4.1

4.3

16-24

Zn

21.8

-

4.0

3.8

4.1

4.2-9.7

Cr

4.4

0.59

1.0

0.97

1.0

9.6-16

Sn

3.8

0.76

0.96

0.66

0.75

-

Ni

5.0

0.062

0.82

1.0

1.0

-

V

4.1

0.78

0.29

1.1

1.0

-

Mo

4.7

0.31

-

0.25

0.23

-

Pb

0.84

0.14

0.19

-

0.20

64-80

Cd

0.46

0.013

0.086

0.094

0.090

6.7-10

Cs

0.45

-

-

0.018

0.014

-

a

Maximum capacity found at 20-80°C

[7]

- = No data

but only those for the concentrations used in this study. Initial concentrations of the

metals have been found to heavily affect the capacities in batch tests

[16, 17]

.

Higher capacities than presented here were found

[7]

, due to the much higher metal

concentrations used, up to 10 g/L. The capacity order was: Pb > > Cu > Cr > Cd >

Zn; following the order of the metals' electronegativity and hydrated ionic radii.

This order may also be explained by the metals' electron configuration and ligand

field stabilization energy (LSFE), as found by

[16]

.

The results of the batch tests, that is initial and final concentrations, were used

to calculate the Freundlich adsorption isotherms for each metal. The calculations

yielded the coefficients n and KF, and the regression coefficient R2, which show