Environmental Engineering Reference

In-Depth Information

Determination of the effective probability of detection

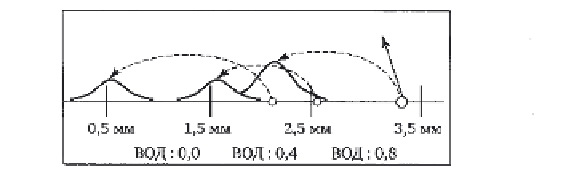

Figure 9.18 shows the statistical modelling procedure. Let a crack 2.7 mm

long be detected for the first time at the

i

i-th ISI. The history of growth of

this crack can then be obtained by inverse modelling of crack growth. Since

PDD is a function of crack size, the value of PDD can be calculated for each

ISI. From these values we can calculate the actual PDD, i.e. effective PDD.

Repeating the simulation many times, the average value of the effective PDD

can be determined.

For a particular inspection method the effective PDD is regarded as a

function of crack size for each ISI. The number of actual cracks of a given

length or length range can be obtained from equation [9.13].

The curve effective PDD for each ISI is plotted using the following

procedure in which crack growth is simulated by the Monte Carlo

method. The curve of effective PDD in the

k

-th ISI is obtained as follows:

1) a crack with length

a

i

in the

k

-th ISI is considered;

2) reversed crack growth back to the size of the minimum detectable

crack length is simulated. A random variable

Z

is renegerated during

simulation and, using equation [9.1], the crack growth rate is calculated;

3) the size of the crack and the corresponding values of PDD for each

of the previous cycles of ISI are determined;

4) the resultant PDD values are used to calculate the effective value;

5) many estimates of the effective PDD are produced, repeating steps

(1) to (4), and the average effective PDD is calculated.

6) steps (1) to (5) are repeated for increasing length

a

i

+ Δ

a

to the

k

-th

ISI and the average value of effective PDD are determined for different

crack sizes.

PDD values used in the simulation are presented in Table 9.1. Modelling

was carried out using discrete PDD values, as it is more convenient to

calculate the number of actual cracks.

Discrete and continuous PDD curves, used in the simulation in each

ISI, are shown in Fig. 9.19. Since the non-destructive testing system was

changed after the 9th ISI, the PDD

curve also changed after the 9th ISI.

The effective PDD was used to estimate the actual number of defects

with the inspection results taken into account. Figure 9.20 shows the

2.7 mm detected cracks

0.5 mm

1.5 mm

2.5 mm

3.5 mm

PDD: 0.0

PDD: 0.4

PDD: 0.8

9.18

Scheme of statistical modeling to assess the history of the

crack growth.

Search WWH ::

Custom Search