Environmental Engineering Reference

In-Depth Information

8.3 Optimisation of the technical inspection and

scheduled preventive maintenance

8.3.1 Optimisation of scheduled-preventive

maintenance

Optimisation of scheduled-preventive maintenance (SPM) using probabilistic

methods of structural strength can be performed on the basis of both the

composition of and periodicity of operations.

The simplest approach is to monitor the actual level of reliability

of components and pipes which are important for safety. SPM of these

elements should be carried out on the basis of the criterion of reaching an

unacceptable level of reliability.

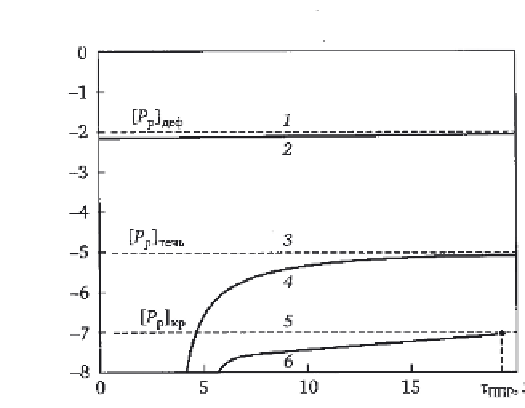

Figure 8.16 shows schematically the change in the probability of the

existence of discontinuities with the unacceptable size in equipment in

operation (curve 2), the probability of leaking (curve 4) and the probability

of failure of the structural element (curve 6). SPM should be carried out

when unacceptable values of probabilities are recorded.

The case of expulsion from the SPM of eddy-current testing of tubes of

steam generators reactors VVER-440, units 3 and 4 of the Novovoronezh

NPP, is described in section 9. The volume of these operations was

reduced on the basis of analysis of the reliability of the tubes which, after

lg

P

f

(τ)

[

P

f

]

def

[

P

f

]

leak

[

P

f

]

cr

τ

SPM

, years

8.16

Time of next scheduled-preventive maintenance determined

using the reliability characteristics on the basis of the criteriaof

maximum detectability of unacceptable discontinuities in operation

lg

P

f

(

τ

) (curve 1 - normative and 2 - actual), the maximum probability

of leakage (curve 3 - regulatory and 4 - actual) and the maximum

probability of failure (curves 5 - regulatory and 6 - actual).

Search WWH ::

Custom Search