Environmental Engineering Reference

In-Depth Information

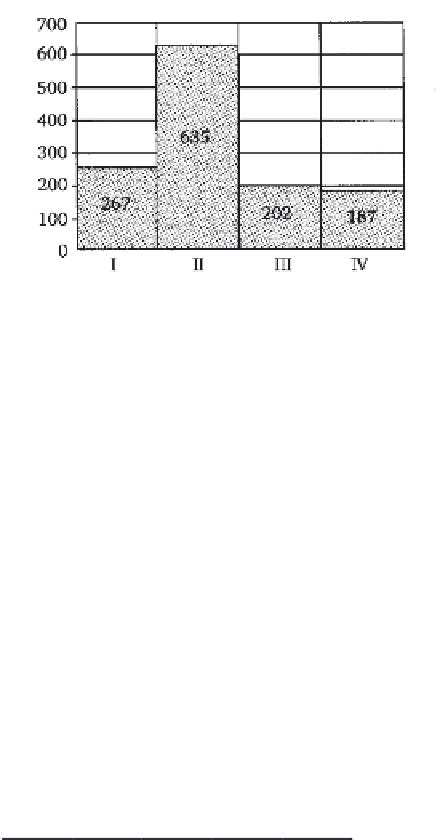

7.21

Number of defects in welded joints in DN800 pipelines and

repeated forced circulation collectors of RBMK reactor detected

by NI methods and repaired at the manufacturing plant (Dzhuro

Dzhakovich): I) inspection after welding (radiography); II) inspection

after welding (ultrasound); III) inspection after heat treatment

(ultrasound); IV) superinspection prior to delivery of pipeline

(ultrasound).

did not reveal any defects (see below):

1990 - 78 welds inspected (9 field, 18 shop, 51 longitudinal). Defects

were not detected;

1991 - 160 welds inspected (26 field, 34 shop, 100 longitudinal). Defects

were not detected.

1992 - 371 welds inspected (89 field, 71 shop, 211 longitudinal). Defects

were not detected.

1993 - 182 welds inspected (89 field, 32 shop, 61 longitudinal). Defects

were detected.

1994 - 191 intersections inspected. Defects were not detected.

Table 7.4

Results of ultrasound inspection of DN800 pipelines of repeated

forced circulation circuit of unit 1 of the nuclear power plant shown as the

ratio of the number of identified discontinuities to the number of tested welds

Field welds

Shop welds

Year of

control

circumferential

circumferential

longitudinal

1

2

3

1

2

3

1

2

3

1989

71

4

0.056

46

1

0.08

-

-

-

1990

48

13

0.27

25

3

0.12

100

2

0.02

1991

86

18

0.21

48

11

0.23

97

2

0.021

1992

156

25

0.16

46

13

0.28

251

0.032

1994

112

25

0.22

34

0

0

109

9

0.08

Total

524

85

0.16

199

28

0.14

557

21

0.037

Note. 1. Inspected number of welds. 2. Number of defective welds. 3. Ratio of the number

of defective welds to the number of inspected welds.

Search WWH ::

Custom Search