Environmental Engineering Reference

In-Depth Information

by ten or more times. Introduction of economically optimum standards of

defects to operating nuclear power plants reduces the labour content and

exposure doses ten times while improving their safety (due to reduced

maintenance, additional analysis of strength and operating life and resources

and the use of freed-up resources to increase safety during operation).

7.4.3 Cost-optimum time interval between inspections

(deterministic approach)

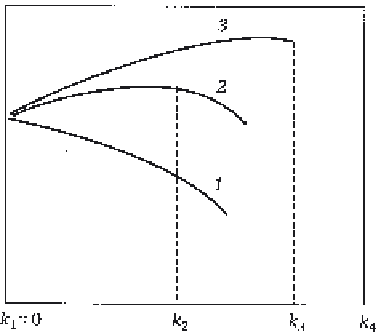

The time interval between inspections (or frequency of inspection) affects

the economic factors.

Figure 7.16

106

shows the dependence of the income earned in the

operation of structures (e.g. NPP) on the frequency of inspection for the

entire period

k

.

Curve 1 corresponds to the case when inspection of the element of the

structure (or the entire object) is economically not advantageous, i.e. losses

from its unreliable operation are small and do not exceed the cost of

inspection, and the optimum frequency of inspection

k

1

is then equal to 0.

Curve 2 corresponds to the case when the income from operation in

inspection at a low frequency increases but the inspection volumes increase

dramatically and the total revenue from operation begins to fall. The

maximum point on curve 2 corresponds to the economically optimum

inspection frequency.

Curve 3 corresponds to the constructions whose failures have catastrophic

consequences and are unacceptable for society. Any inspection costs in this

case are much smaller than the losses due to the accident. The optimum

inspection frequency

k

3

at which the 100% reliability of the structure is

reached (100% reliability can be unattainable and it can be replaced by

another that is acceptable).

Inspection frequency

7. 1 6

Determination of optimum inspection frequency.

Search WWH ::

Custom Search