Environmental Engineering Reference

In-Depth Information

7. 8

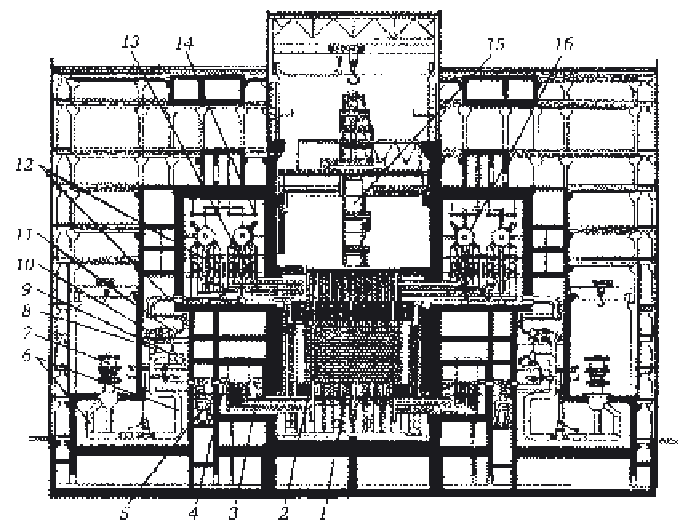

RBMK-1500 reactor of unit 2 of Ignalinsk nuclear power

plant: 1) graphite stack; 2) fuel pipe of fee channel; 3) water

pipeline; 4) distributor; 5) emergency core cooling pipelines; 6)

standpipe; 7) MCP; 8) suction pipeline; 9) pressure header; 10)

bypass pipe; 11) suction header; 12) risers; 13) steam pipelines; 14)

steam pipeline; 15) refueling mechanism; 16) drum separator.

• To avoid the need for evacuation to a distance outside the zone

established in the standards for nuclear installations, measures must

be taken to ensure that the probability of worst case emergency

release of radioactive material does not exceed 10

-7

reactor·year.

• in addition, it is stated that the core damage frequency should be

less than 10

-5

reactor·year.

However, in Lithuania as well as in most other states members of the

IAEA, there are still no regulatory requirements (even in the framework of

PSA) to achieve the stated values of security.

As PSA shows, it is important to enhance the safety of the Ignalinsk

nuclear power plant. One of the main risk factors was ageing of the pipeline

DN300 by stress corrosion cracking. These pipelines are shown in Fig. 7.9.

In Fig. 7.10 shows an increase in the number of detected defects with

operating time.

The main purpose of non-destructive testing (NDT) is to detect possible

degradation in its early stages and prevent the damage that can lead to

destruction. In this regard, the goal to develop a NDT programme based

on risk information.

Search WWH ::

Custom Search