Environmental Engineering Reference

In-Depth Information

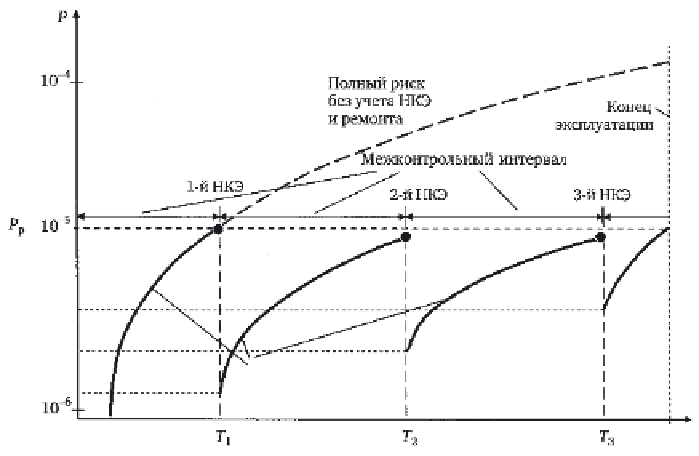

Total risk, ISI and

repair not taken

into account

End of service

2

nd

ISI

3

rd

ISI

1

st

ISI

P

f

Total risk, ISI

and repair taken

into account

P

in

7. 7

Frequency of ISI taking the risk factor into account (numerical

values are purely illustrative).

values of risk during the operation of this component (Fig. 7.7).

If the initial level of component failure probability is

P

in

, then during

operation due to the development of various processes of damage in the

metal of the component the failure probability will increase. When the

probability Pf reaches the permissible value [

P

] at which ISI and repair

must be carried out, the component is either decommissioned or measures

are taken to decrease the probability of its failure. Such measures may

include ISI and subsequent repair of identified defects. After ISI and

repair, the failure probability of the component decreases (in Fig. 7.7 this

corresponds to times

T

1

,

T

2

and

T

3

. However, as mentioned by the authors

of the studies in question, the initial level of probability of failure is not

reached because of the irreversible degradation of metal and possible

residual defectiveness of the component. When the possibility of reducing

the probability of failure due to ISI and repair is exhausted, the component

reached the end of its operating life.

7.3 Optimisation of the risk-based oriented

in-service inspection at the Ignalinsk nuclear

power plant

111

The scheme of the reactor RBMK-1500 of the unit 2 of the Ignalinsk nuclear

power plant is shown in Fig. 7.8.

The Lithuanian nuclear regulatory authorities require:

Search WWH ::

Custom Search