Environmental Engineering Reference

In-Depth Information

N

res

;

N

in

;

N

det

, 1/mm

5.46

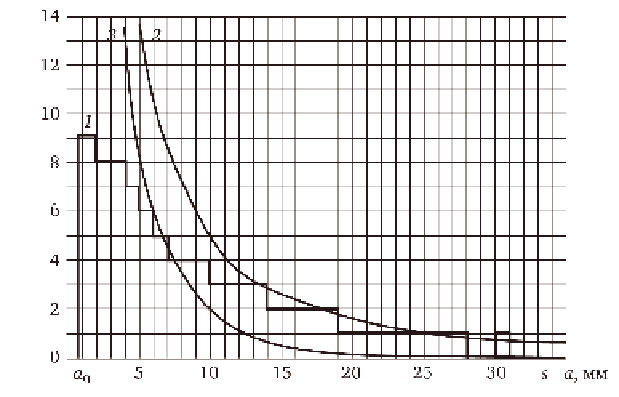

Histogram of defects detected in NDT and the envelope of

the defects 1; the curve of initial detectiveness 2; curve of residual

defectiveness 3.

Example 2

It is required to determine the probability of safe operation of pipelines

which can be in the 'leak before fracture' state.

There are 100 pipelines of the same type produced from seamless steel

pipes. In the welded joints distributed across the pipeline axis, ultrasonic

inspection prior to the start of service revealed technological defects

oriented in the transverse plane situated normal to the pipeline axis. The

defects were schematised by the same procedure as in the previous example

(Fig. 5.42).

The service life of the pipelines was 20 years. During this period, each

pipeline was subjected to 1500 internal pressure cycles.

Non-destructive inspection of all pipelines revealed a specific number of

crack-like defects in each pipeline. All the detected defects were schematised

by ellipses, and the minor semi-axis

a

=

F

/

π

c

, where

F

is the area of the

defect, was determined for each ellipse.

The number of cracks of each standard size, detected in the 100

pipelines, was summed up and the mean value was determined:

N

det

(χ) =

N

det.mean

(χ) = [

N

det1

(χ) +

N

det2

(χ) +

N

det3

(χ)+...

N

det100

(χ)]/100.

The average values of the number of the detected defects were used to

construct a histogram (Fig. 5.46, curve 1).

A test specimens with planar hidden defects was produced. The results

of inspection of the specimens were used to determine the reliability

Search WWH ::

Custom Search