Environmental Engineering Reference

In-Depth Information

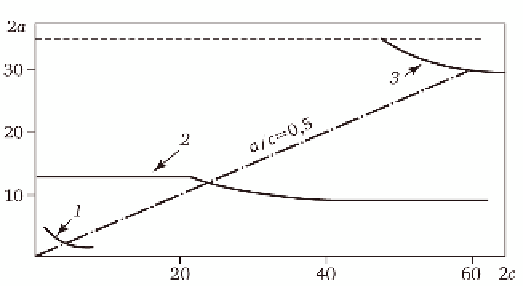

Length of discontinuity

5.43

Set of discontinuities of critical size 3, size permissible in

service 2 and permissible in manufacture 1.

defectiveness on the semilogarithmic scale are shown in Fig. 5.45.

The product is inspected by non-destructive testing products using the

selected method technical means of inspection (ultrasonic, eddy current,

radiographic, or others) as well as by operators of certain qualifications.

The discovered defects are then removed.

The inspection results are represented as a histogram in the 'the

characteristic size of the defect χ - the number of identified defects of the

given size

N

det.comp.

' coordinates.

This is followed by determination of the probability of defect detection

P

pdd

, initial defectiveness

N

in

=

f

(χ) and residual defectiveness

N

res

= φ(χ)

as the difference between

N

in

and

N

det

.

These relations can be determined by various methods.

According to

one of the methods,

the NDT results are presented in the

form of analytical expressions.

The structure of the equation which can describe the NDT results,

presented in Fig. 5.44, is the following:

N

det

(χ) =

N

in

(χ)

R

dd

(χ),

where

N

det

is the number of defects detected in inspection in the unit of the

characteristic size. If as the characteristic size is represented by the minor

axis of the ellipse which schematises the defect, then the unit

N

det

- mm

-1

;

N

in

is the function of the initial (prior to NDT and repair) defect with the

same unit as the

N

det

;

P

dd

is the probability of detecting a defect of given

size χ.

The type of functions

N

in

and

P

dd

is defined on the basis of the simplest

expression, the minimum number of constants and the correspondence of the

physically defined dependence of

N

in

and

P

dd

on χ. In the first approximation

the following equations can be used:

Search WWH ::

Custom Search