Environmental Engineering Reference

In-Depth Information

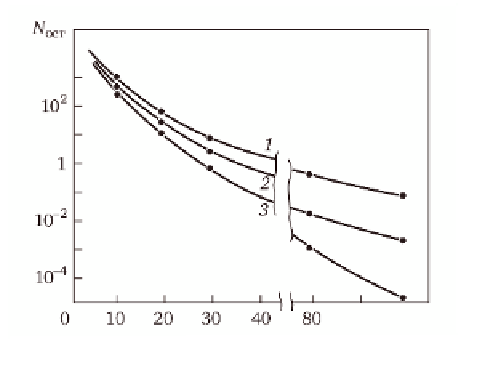

N

res

Crack length, mm

5.38

Number of remaining cracks in the cladding of a pressure

vessel: 1) before inspection, 2) after first inspection, 3) after

second inspection.

the functions

W

and

N

in

is reduced to determining the unknown constants

A

,

n

and α. The constant

a

0

is easy to find from the inspection results.

The coefficient

A, n

and α can be determined from the condition of

maximal proximity of the calculated curve to the experimental one.

Table 5.9 shows the constants

A, n

and α, obtained by analyzing the

results of flaw inspection at nuclear power plants during entry inspection

and commissioning works. The cladding of the reactor vessel was inspected

by dye penetrant inspection, the pipelines by ultrasonic testing.

Figure 5.38 shows the results of analysis of initial and residual

defectiveness in the cladding of the reactor pressure vessel. Curve 1

characterises the initial defectiveness of the cladding after factory inspection

in the plant and before inspection at the nuclear power plant. Curves 2

and 3 characterise the residual defectiveness after two inspections at the

nuclear power plant.

5.2.4 Possibility of predicting the results of repeated

inspection

Generalising equation [5.21] to the case of the k-th inspection gives the

equation:

89

{

}

[

]

[

]

k

−

n

(

N

)

=

Aa

exp

(

k aa

1)(

−α −

)

1

exp

−

(

aa

−

)

−α −

.

[5.22]

det

0

0

Determining the constants

A, n

, α and

a

0

from the results of the first

inspection, as described above, the results of subsequent inspections can

be predicted.

Comparison of results of repeated inspection of the cladding of the

reactor casing during start-up operations by the dye penetrant method with

Search WWH ::

Custom Search