Environmental Engineering Reference

In-Depth Information

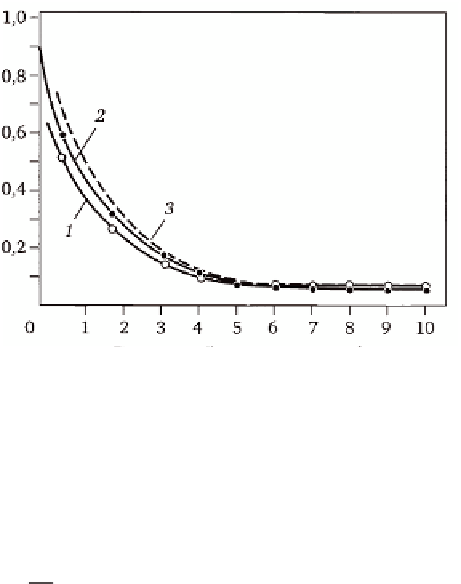

Order number of inspection k

5.36

Residual defectiveness after

k

inspections;

N

res

is the number

of undetected defects in inspection;

N

in

is the total number of defects

in the test sample DN800, 1) experimental curve, 2) calculated

curve at

ε

= 0, 3) calculated curve with

ε

= 0,05.

[

]

(

N

)

k

=

N

k

−

1

(1

exp

−

(

aa

−α −

[5.17]

)

res

res

0

or

A

[

]

(

N

)

k

=

exp

kaa

(

−α −

[5.18]

) .

res

0

a

n

Calculations using equation [5.17] yielded the calculated curve (2) (Fig.

5.34). Curve 1 in Fig. 5.36 is the result of an experiment conducted on a

test specimen DN800 made of steel 22K.

Figure 5.36 shows the satisfactory agreement between the calculated

and experimental curves. The observed discrepancy in the curves for the

number of inspections

k

> 6 is of fundamental nature. The theoretical curve

2 tends to 0 with the increase in the number of inspections, whereas the

experimental curve tends to 0.05. The value ε = 0.05 is determined by the

limited capacity of the inspection method. If the detection of defects is

described by equation [5.5], setting ε = 0.05, then there is better agreement

between the calculated curve 3 and experimental curves 1 for the number of

inspections

k

> 5. Curve (3) was plotted using the modified equation [5.18]:

(

)

[

]

N N

=

exp

kaa

(

− α −

)

.

[5.19]

+ε

res

in

0

Equation [5.19] holds in the region

ln(1

−ε

)

.

aa

≥−

[5.20]

0

k

Search WWH ::

Custom Search