Environmental Engineering Reference

In-Depth Information

by the PISC members;

• preparation of technical reports on issues of rules and standards and

transfer them to the authorities responsible for the development of

normative documents.

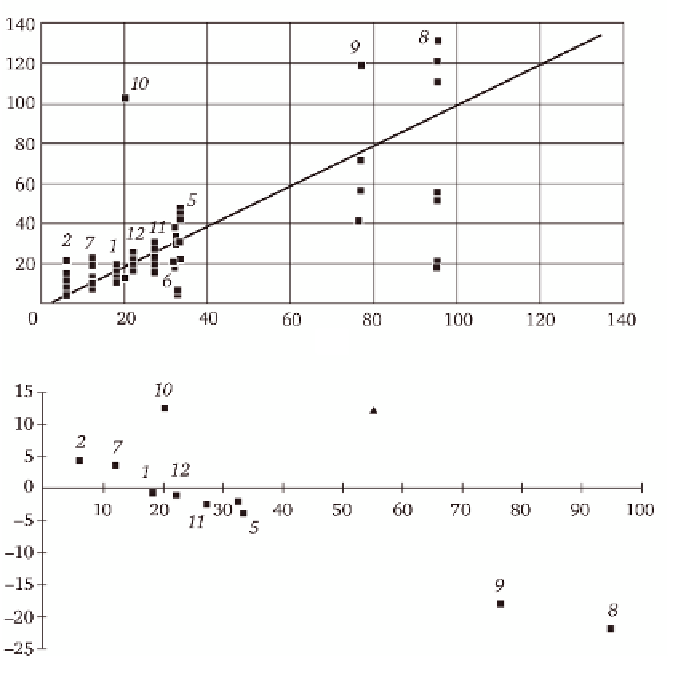

The main results of these studies are summarised concisely below. The

results of studies of the reliability of the linear dimensions of discontinuities

in the direction of the wall thickness in inspection on the full-scale model

of the reactor vessel are described in Fig. 5.23. As can be seen, the error

in determining the depth of the discontinuity may reach significant values,

both in the direction of understating the size and in the direction of

overstatement. Figure 5.24 and 5.25 show defects No. 8 and No. 9 (see

Fig. 5.23) for which the errors in detection were the highest.

The results of the study of the probability of detecting defects in

austenitic steel are shown in Fig. 5.26. 5.27, and the test samples on which

a)

b)

Actual size, mm

5.23

Variation of the size of defects (except for defects Nos. 3

and 4) according to the results of inspection by all groups of NDT

inspectors (a) and dependence of the error in determining the

size of defects in the direction of the wall thickness of the reactor

vessel on the actual size of the defect (b).

Search WWH ::

Custom Search