Environmental Engineering Reference

In-Depth Information

Table 5.5

Integrated assessment of the detection of discontinuities

VNIIAES

(Bauman)

VNIIAES

(YuTe)

SUMIAD

(YuTe)

Parameter

Radiography

N

det

15

19

15

20

K

d

0.60

0.76

0.60

0.80

K

p

0

1

4

4

The dependence of the detectability of discontinuities on the length

of the defect was estimated as follows. The data on the length of the

defects were represented by the data from the test sample certificate,

and investigations were carried out on discontinuities corresponding to

those embedded in the preparation of the test sample and confirmed by at

least two different methods of ultrasonic testing and/or radiography. The

dependences obtained are shown in Fig. 5.13.

The detectability of defects using different inspection methods of was

also analysed for the main circulation line DN 800 of the RBMK-1000

reactor.

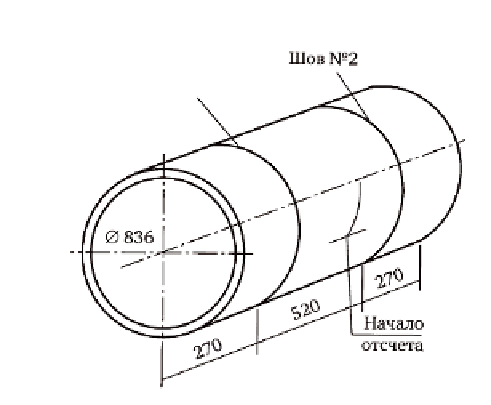

A test sample (see Fig. 5.6 and 5.14), made of three coils of pipe

DN800 was used in this case. The pipe material was steel 22K, clad with an

austenitic deposit (in this case, imported steel KREZELSO was used). The

test sample contained two welded joints: repair and assembly. In this topic,

attention is only given to the results of inspection of the assembly weld No.

1 in plane and volume defects were produced (incomplete fusion of the weld

root, incomplete fusion with the edge, slag and pores). Assembly weld No.

1 (Fig. 5.15) is based on standard technology of manual arc welding with

Weld No. 2

Weld No. 1

Start of

measurement

5.14

Diagram of the test sample DN800 of the main circulation

pipeline of the RBMK-1000 reactor.

Search WWH ::

Custom Search