Environmental Engineering Reference

In-Depth Information

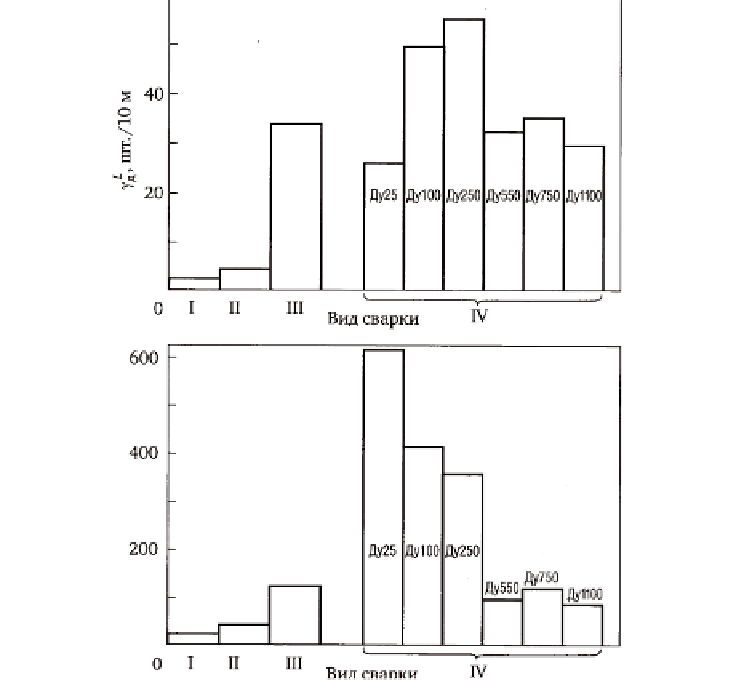

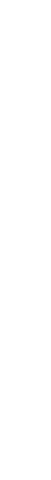

DN550 DN750

DN1100

DN25

DN100 DN250

Welding method

DN25 DN100

DN250

DN750

DN550

DN1100

Welding method

5.1

Diagrams of specific defects in welds in steam generator

casings (I-III) and nozzle welds (IV) under different types of welding

ised: I, II - respectively, electroslag, automatic submerged arc; III,

IV - manual electric welding.

In conducting successful hydraulic tests, if an

a

cr

<

s

, the dependence

N

(a) corresponds to that shown Fig. 5.2c.

The dependence

N

(

a

) also affects repair according to the results of flaw

inspection (Fig. 5.3). The value

a

0

in Fig. 5.3 corresponds to the rejection

size of the defect.

The curves

N

(

a

) (see Fig. 5.2) can be called curves that characterise real

defects in a construction. Curve 2 in Fig. 5.3 corresponds to the residual

defectiveness remaining in the structure after inspection and repair of real

defects. For brevity, the term 'residual real defectiveness after inspection

and repair' will be replaced by the term 'residual defectiveness'.

The actual initial (prior to inspection) defectiveness and residual

defectiveness should distinguish between themselves and also should be

Search WWH ::

Custom Search