Biology Reference

In-Depth Information

heat transfer, i.e. the temperature difference, is largest at the beginning,

and declines towards the end of the crystallization. This leads to the tem-

perature falling quickly at the beginning, and slower towards the end. The

normal thing therefore is for a massive, uncontrolled primary nucleation

to occur early, resulting in a small product size. Large variations will be

observed from one batch to another. If large crystals are desired, a careful

generation of supersaturation is called for, in particular at the beginning of

the process. As the crystal surface area consuming the supersaturation

increases, it is possible to generate supersaturation faster. This procedure

is called

controlled cooling

(Mullin, Nyvlt, 1971) and the main principle

is that careful cooling should be employed initially, followed by a gradual

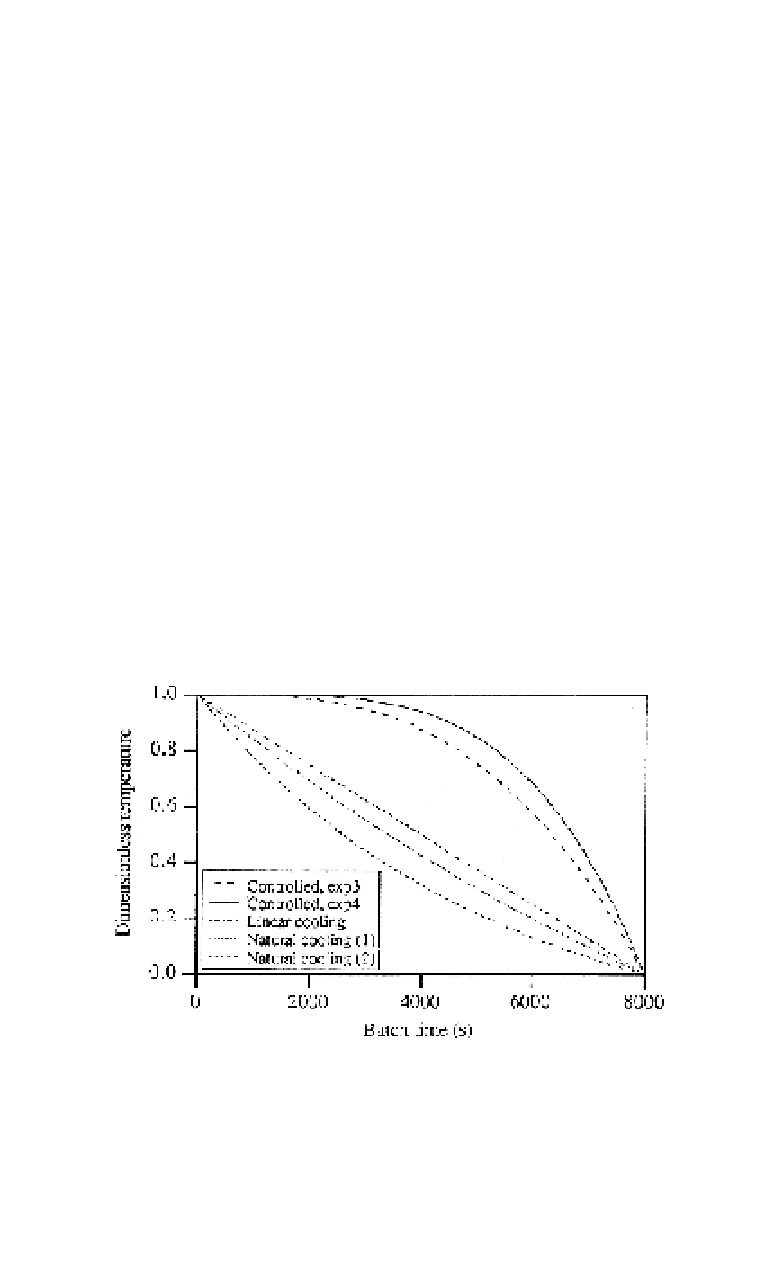

increase in cooling rate as the total crystal surface area increases. In Fig. 8,

a few different controlled cooling profiles are shown, together with two

examples of natural cooling profiles.

In the case of natural cooling, supersaturation peaks very high and

marked, leading to a powerful primary nucleation early on in the process.

Fig. 8.

Different cooling profiles in batch cooling crystallization. The diagram shows the

temperature of the solution as (

T

0

−

T

f

) versus time when the batch is cooled from

the initial temperature,

T

0

, to the final temperature,

T

f

.

T

is the current temperature. In con-

trolled cooling, different exponents,

T

)/(

T

0

−

α,

can be used in the equation describing the cooling

profile: (

T

0

−

(

t

/

t

f

)

α

, where

t

f

is the total cooling time. Natural cooling is

described in the text and is given in the figure for two different final temperatures at equal

cooling water temperature.

T

)/(

T

0

−

T

f

)

=

Search WWH ::

Custom Search