Environmental Engineering Reference

In-Depth Information

n

-type

p

-type

anode

electron

acceptor

electron

donor

cathode

(a)

(b)

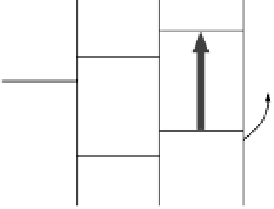

Figure 6.10 More general single-bandgap

devices. Schematic [74] of p

and CuIn

1x

Ga

x

Se

2

CIGS

cells, and to

individual elements of tandemcells, generally of

high efficiency. Figure 6.10b applies to

organic

polymer

cells, generally of low efficiency and

low cost. The third type of cell, the

dye-

sensitized solar cell,

is not shown. Multiple

junction (tandem),

intermediate band,

and

quantum-dot-assisted cells are additional

categories (see text).

n junction (a) and

an organic bilayer structure (b) under

illumination. Illumination leads to output

voltage and current in external circuit. In (a),

light can be usefully absorbed in wider region

than the depletion layer, whose width includes

the diffusion lengths for minority carriers in the

semiconductor regions on both sides of the

actual junction. Figure 6.10a applies to Si, GaAs,

-

6.3

CIGS (CuIn

1x

Ga

x

Se

2

) Thin-Film Solar Cells

Low-cost semiconductor cells with ef

ciency approaching 20% have evolved making

use of alloys of selenides of copper, indium, and gallium (CuIn

1

x

Ga

x

Se

2

, known as

CIGS). These crystalline alloys are typically P-type semiconductors with appropri-

ate bandgaps, high absorption coef

cients, and quite large diffusion lengths. The cell

is typically in the formof a thinN-layer placed near the front of an absorber of CIGS

with thickness about 1

m. The PN junction, as in Figure 6.10a, sends electrons and

holes in opposite directions. The ef

ciency limit in these cells seems to be about 20%,

with 15%available in preliminary large-scale production. This is in the same range as

polycrystalline Si cells, but it appears that the CIGS cells are easier to fabricate on

large scale and can be much cheaper to produce. These cells are made commercially

by Avancis, Nanosolar, Honda Soltec, Solar Frontier, Wurth Solar, and Global Solar.

The historical origin of this line of CIGS cells may have been the CdS/Cu

2

S cell

formed by chemical surface treatment of CdS. This cell fell out of favor partly because

of the toxic nature of Cd.

m

6.3.1

Printing Cells onto Large-Area Flexible Substrates

The reasons for ascendancy of CIGS include ef

ciency and durability, but the main

reason is that these cells can be manufactured, without vacuum equipment, on a roll-