Agriculture Reference

In-Depth Information

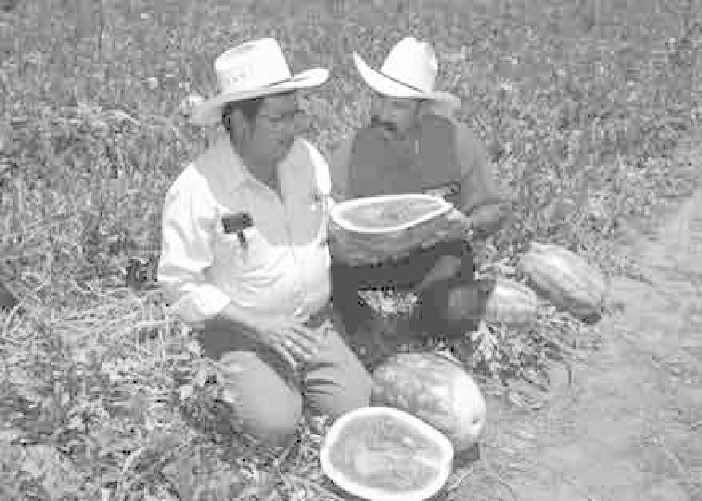

Plate 15.1

Two men inspecting a watermelon

Because of the investment and cost of inventory, effective inventory management is a key

factor driving profi tability for many agribusiness fi rms. Photo courtesy of USDA Natural

Resources Conservation Service.

inventories to be received is also kept, to eliminate the dangers of ordering too much. Several

forms of automated continuous inventory tracking systems exist. Bar-code scanners at super-

markets, for example, are a technology that enables inventories to be tracked continuously

and product to be replenished as it is purchased.

One advantage of continuous systems is that the inventory count is always current. The

disadvantage is that even with a sophisticated, computerized inventory system, the reliability

of the inventory quantity on-hand is only as good as the people who update it. The integrity

of the system will be lost if employees forget or by-pass the system. Theft and shrinkage also

will affect the accuracy of the continuous inventory system.

Distribution

Customers, markets, and competitors are always changing. Manufacturers have numerous

options and resources available to them to distribute their products to the ultimate end

consumer. Therein lies the challenge of managing the distribution element of supply

chain management.

Physical distribution systems (PDS)

are the series of marketing

channels through which parts, products, and fi nished inventory are stored and moved from

suppliers, among outlets, and ultimately, to consumers. PDS encompasses transportation,

storage/warehousing, and delivery of the fi nished product to the ultimate consumer.

PDS must be carefully managed and coordinated to meet delivery requirements of business