Biomedical Engineering Reference

In-Depth Information

The effect of margin engagement is incorporated into the equation by

adding a spring constant, making the model a function of the depth of

penetration into the hole:

..

.

M

C

K

F

ext

r

..

r

.

rM

m

c

m

M

,

m

m

c

2

k

(1

k

z

)

m

c

K

rm

2

c

k

(1

k

z

)

m

where: m, c, k - mass, damping, stiffness, ξ - η - tool fixed frame

It has been experimentally confirmed that the drill natural frequency

increases with the depth of the hole. By showing that this doesn't happen when

machining a tube, it has been proven that the margin effect is the sole reason

of this frequency increase. Both of Dilley's papers have been aimed at

obtaining and constructing predictive models for engineers with the aim of

drilling process optimization.

2.2. Bending Model

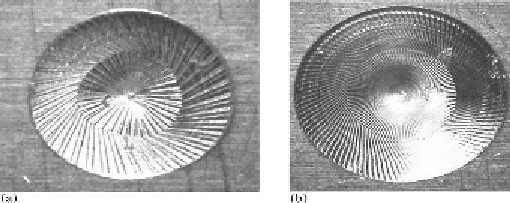

Apart from the axial and torsional vibrations, bending vibrations have

been found to be common in the drilling process as well. It has been suggested

that bending vibrations have a more detrimental effect on hole quality due to

the fact that the hole form changes drastically with the effect of bending

(Figure 6).

Figure 6. Striations in the bottom of the hole caused by vibration of the drill: (a)

bending chatter; (b) torsional chatter [18].