Biomedical Engineering Reference

In-Depth Information

1.

I

NTRODUCTION

Chatter is considered to be a self excited vibration between the machine

tool and the workpiece [1, 2]. Regenerative chatter is the most important type

of chatter and it is a consequence of both the previously cut surface and

current chip formation. As the tool is creating a new cut surface by removing

material in a form of a chip, it leaves waviness in the profile that consequently

affects the next cut. The new wavy surface induces vibrations in the tool that

then affects the surface (Figure 1). Chatter is a great problem in cutting due to

the fact that it causes decrease in tool life, limited productivity, bad surface

finish, poor tolerances as well as unacceptable noise. Chatter problems in

turning and milling have been covered extensively throughout the years and

can easily be found in literature [1-4].

There are many papers dealing with the analytical models for prediction of

maximum stable depths of cut as function of spindle speeds. This way, optimal

operating regimes have been defined for both turning and milling operations

resulting in the use of large depths of cut and large spindle speeds

simultaneously. Some researchers went even further and developed computer

programs for chatter prediction [5].

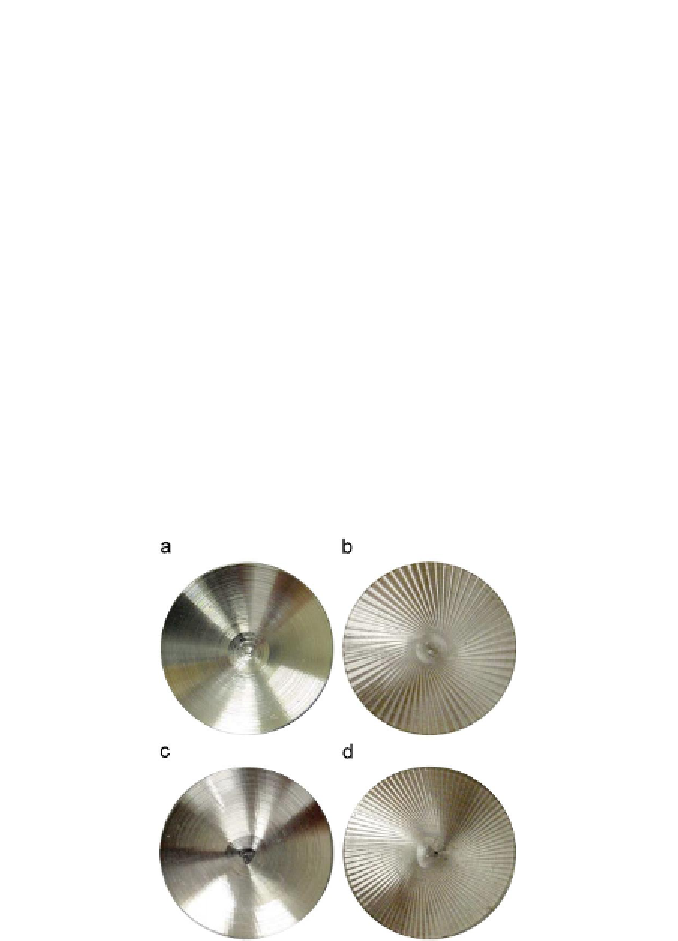

Figure 1. Hole shapes: (a) stable cut, no visible vibrations; (b) sunray pattern due to

unstable torsional-axial chatter vibration; (c) trigon caused by whirling vibrations and

(d) surface resulting from combined torsional-axial chatter and whirling vibration [6].