Biomedical Engineering Reference

In-Depth Information

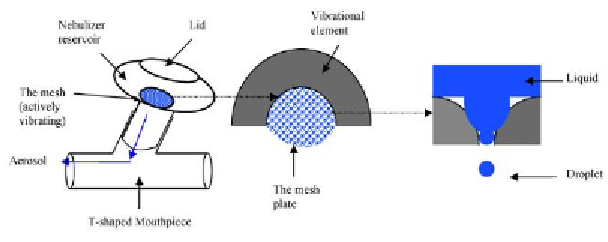

Alternatively, actively vibrating-mesh nebulizers generate aerosols by

employing ―micropump‖ technology that consists of an aerosol generator of up

to 1,000 electroformed dome-shaped apertures surrounded by a ceramic

vibrational element (Fink et al., 2001a; Gopalakrishnan and Uster; 2001;

Dhand, 2002) (Figure 12). The vibrational element expands and contracts

when an electrical current is applied, which results in upward and downward

movements of the mesh by a few micrometers (Dhand, 2002). This technology

generates slow-moving aerosols with the droplet size and nebulization rate

being dependent on the aperture size of the mesh (Gopalakrishnan and Uster,

2001) and fluid physicochemical properties (Ghazanfari et al., 2007; Elhissi et

al., in press). The Aeroneb Pro (Aerogen, Ireland) (Figure 12) nebulizer uses

this technology and is recommended for use during mechanical ventilation

since it can be connected to the inspiratory limb of the ventilator circuit whilst

nebulization is continuously operating (Fink et al., 2001a).

(Source: Ghazanfari et al., 2007).

Figure 12. Design of the Aeroneb Pro nebulizer which operates by utilizing an

Aerogen aerosol generator (OnQTM) comprising a piezoceramic vibrational element

surrounding the mesh plate.

In contrast to ultrasonic and air-jet nebulizers, the fluid temperature does

not change during atomization (Fink et al., 2001a). Aerogen vibrating-mesh

nebulizers have been reported to be as efficient as jet nebulizers in delivering

suspensions of ciclosporin (Eskandar et al., 2003), steroid (Fink et al., 2001b;

Fink and Simmons, 2004) and liposomes (Elhissi et al., 2006; 2007; Elhissi et

al., in press).

As an alternative to the micropump technology, TouchSpray technology

can also generate slow moving aerosols. The novel vibrating-mesh (electronic)

nebulizer eFlow (Pari, GmbH, Germany) has a TouchSpray atomizing head

which incorporates a piezoelectric actuator and a perforated membrane which