Biomedical Engineering Reference

In-Depth Information

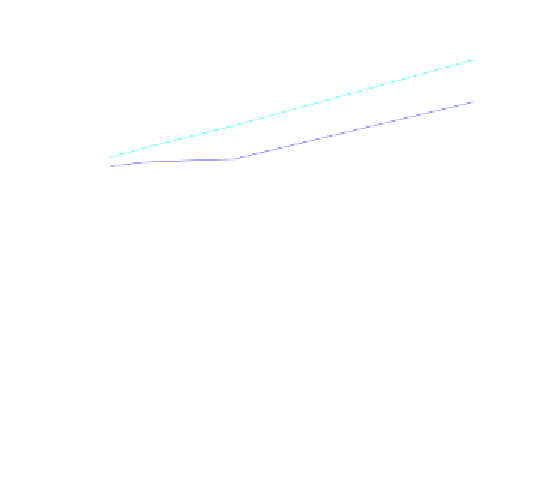

that as the rotating speed of the rotor increases, pressure coefficient increases

and the pressure coefficient values are almost the same for all geometries with

the increase in rotational speed similar to the previous case.

Reproduced with permission. Copyright retained by Inderscience Publishers.

Figure 3. Variation of Pressure Coefficient with Rotational Speed for Two- Stage

Rotor and its Modified Geometry.

From Table 2 It can be concluded that for both half-million rpm and one

million rpm rotating speed of rotor, rotor with three inlets inclined at an angle

of 45-degree is the optimum design compared to the other geometries of the

rotor considered after modifying the rotor geometry and for two million and

five million rpm rotational speed of the rotor, the rotor with twelve blades is

the optimum design of rotor for high-speed spindles compared to the other

geometries of the rotor. Rotor geometries considered for numerical simulations

of high-speed spindles were the two-stage rotor and its modified geometry.

The values of pressure coefficients obtained for different rotational speeds of

these rotors are given in Table 3. The number of control volumes associated

with the numerical simulations of two-stage rotor and its modified geometry

were 522,046 and 521,614, respectively. The maximum number of iterations

considered for convergence control was 200 and the residual target for