Environmental Engineering Reference

In-Depth Information

In addition to the control components essential for operation, further system com-

ponents and auxiliary devices such as valves, a manometer, security devices and

other control instruments are required.

Low-temperature range

High temperature range

Drive energy

Compressor

Vapour

Vapour

From heat source

To heat sink

Heat

(low

temperature)

Heat

(high

temperature)

Low

High

pressure of

refrigerant

To heat source

From heat sink

2-

phase

Liquid

Evaporator

Condenser

Circulating working

medium (refrigerant)

Expansion valve

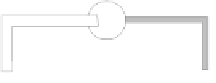

Fig. 9.3

Basic heat pump flow scheme of compression heat pump

(see /9-1/)

The compressor is driven mechanically by an electric or combustion engine.

Combustion motor drives can couple the heat generated by cooling the motor with

the heating process.

The working medium circulating in the heat pump circuit is evaporated in the

evaporator at low pressure and low temperature (even below 0 °C) by adding heat.

The heat is made available by using ambient air or shallow geothermal energy via

a heat carrier intermediate circuit or directly in the case of direct evaporation. The

working medium, now gaseous after the energy withdrawal from the heat source,

is suctioned and compressed by a compressor. During that process its temperature

is increased to a level higher than the flow of the heat utilisation system (i.e. low-

temperature heating system for a residential building). Still under high pressure,

the working medium is then liquefied in the condenser, discharging heat to the

heat utilisation system. Afterwards it flows to the low-temperature section via the

expansion valve. Now the circuit starts again. Evaporator and condenser as the

heat exchanger are the interfaces of the heat pump with the rest of the system.

Sorption heat pumps.

Absorption heat pumps as important representatives of sorp-

tion heat pumps consist of an evaporator, an absorber a desorber and the con-

denser. Two expansion valves and a solvent pump are required for operation.

Whereas a mechanical compressor is used for the compression heat pump, there is

a "thermal compressor" used in the absorption heat pump. Drive energy for this

"thermal compressor" is mainly required thermally (desorber); this thermal drive

energy can be supplied e.g. by gas or oil combustion or by using (industrial) waste

Search WWH ::

Custom Search