Environmental Engineering Reference

In-Depth Information

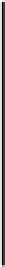

Maximum power coefficient (16/27 bzw. 0.593)

Maximum power coefficient (16/27 bzw. 0.593)

c

p,ideal

c

p,ideal

1/3

1/3

1.0

1.0

Wind speed ratio

v

Wi,

2

/

v

Wi,

1

Wind speed ratio

v

Wi,

2

/

v

Wi,

1

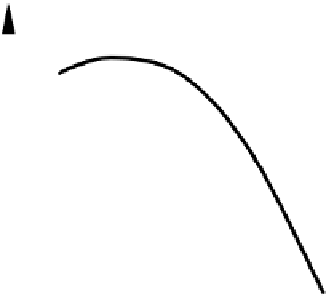

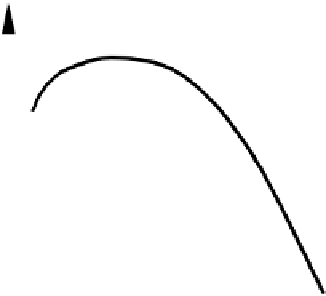

Fig. 7.3

Power coefficient curve relative to the speed ratio between the wind speed in front

v

Wi,

1

and behind

v

Wi,

2

the rotor (i.e. relative to the reduction factor according to Equation

(7.8))

According to Equation (7.8) a maximum theoretical power coefficient of 16/27

is obtained at this ratio. This means that, theoretically, the biggest power extrac-

tion from wind amounts to almost 60 % of the theoretical wind power calculated

according to Equation (7.4). However, due to general physical restrictions, at least

40 % of the wind power of the undisturbed flow that incident on the surface range

of a wind energy converter, is generally unavailable for wind exploitation. One

forth of this loss is due to the incomplete wind slow-down at rotor level (1-

(

v

Wi,

1

2

/

v

Wi

,2

2

)) and to the stream-tube expansion between

S

1

and

S

2

.

However, even for an ideal rotor, wind slow-down to one third of the original

wind velocity presupposes optimum operation conditions (including the rotor

speed in relation to wind speed); this power coefficient is referred to as ideal

power coefficient (

c

p,ideal

= 0.593).

In the 1920s, Albert Betz first published the above theoretical derivation of the

maximum extractable wind power, which is entirely independent from the wind

energy converter type (see /7-2/ amongst other references). On the basis of Betz'

law the described ideal conditions and assumptions have been investigated further

within the scope of extended theories and have continuously improved the de-

scription of real conditions. For instance, impacts of rotational losses (i.e. kinetic

energy that is unavailable due to turbulence of the airflow) which reduces capaci-

ties particularly at low tip speed ratios may be considered.

The tip speed ratio

λ

refers to the ratio of blade tip speed (

v

u

= d

Rot

π n

;

whereby

n

is the number of rotor revolutions and

d

Rot

the rotor diameter) to the

wind velocity at rotor level

v

Wi,Rot

(Equation (7.10)). The lower the number of ro-

tor blades the higher the tip speed ratio.

Especially for modern wind energy converters of few rotor blades (so-called

high speed converters) the power coefficient is determined by the rotor blade's

angular momentum and friction. Within the optimum operation range, the ideal

Search WWH ::

Custom Search