Environmental Engineering Reference

In-Depth Information

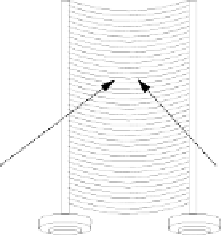

Mounting structure.

The mounting structure of parabolic concentrators is neces-

sarily determined by the shape of the reflector segments or the full-surface con-

centrator. There is a great variety of technical solutions. However, there is a certain

tendency to turntables which at the same time serve as a drive ring. Turntables

permit to minimise material consumption and the drive torque.

Solar tracking system.

Point-focussing parabolic concentrators must be continu-

ously tracking the sun's path to ensure that solar radiation is always parallel to the

optical concentrator axis. Solar tracking systems are further distinguished into

azimuth/elevation and polar tracking systems.

-

For azimuth/elevation solar tracking, the concentrator is moved parallel to the

earth's surface on one axis (elevation axis) and vertically to the earth's surface

(azimuth) on a second axis.

-

For polar (or parallactic) solar tracking one axis is parallel to the earth's rota-

tion axis (polar axis) and the other vertically to the first (axis of declination).

Both systems are available fully automated. As reference parameter for the control

system serve either the solar position, calculated on the basis of date and time of

day, or the signal of a solar sensor.

Receiver.

The receiver absorbs solar radiation reflected by the concentrator and

converts it into technically useful heat. Either the working medium itself or a heat

transfer medium may undergo a temperature rise and/or phase change.

Thus, the highest temperatures of the system occur at the receiver. For systems

which directly heat the working medium, currently common operation tempera-

tures vary between 600 and 800 °C, whereas pressures are between 40 and

200 bar. Intensity distribution of the focussed radiation within the focal spot can-

not be entirely homogenous due to inevitable mirror errors. This is why in addi-

tion, large temperature gradients may occur on the absorber surface /5-21/.

Out of the multitude of available receiver technologies, in the following, two

different systems are discussed.

Capillary structure

Absorber-

tubes

Concentrated

direct radiation

Sodium vapour

Working gas

inlet

Concentrated

direct radiation

Absorber

Re-

heater

Connecting

flange

Working gas

outlet

Liquid sodium

Fig. 5.21

Different receiver types for dish/Stirling systems (left: tube receiver, right: heat

pipe receiver, schematic diagrams according to /5-21/)

Working gas inlet and outlet

Search WWH ::

Custom Search