Environmental Engineering Reference

In-Depth Information

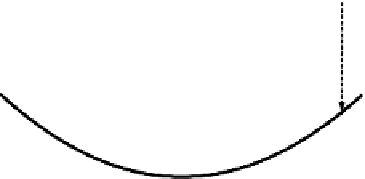

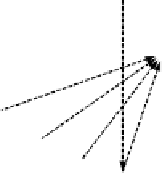

incident radiation onto a certain point or line. Parabola profiles show these proper-

ties (Fig. 5.3 a)). To achieve the highest possible concentration ratio - i.e. the ratio

of reflector surface to absorber surface should be very high for economic reasons

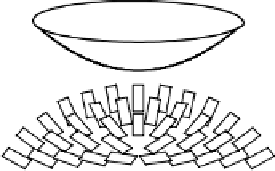

- the profiles are designed as rotational solids (Fig. 5.3 e)). As an alternative, the

reflecting profile can also be extruded, so that the focus is not of point but of line-

shape. These possibilities are outlined in Fig. 5.3 c).

c)

d)

a)

e)

b)

f)

Fig. 5.3

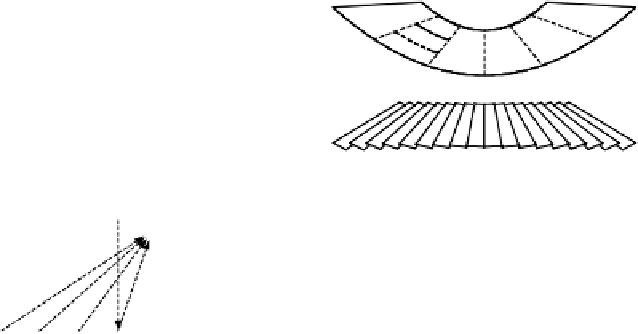

Parabola profiles for radiation concentration (a) parabola profile with ray path,

b) segmented parabola profile (Fresnel) with ray path, c) and d) profiles extruded from

profiles a) and b), e) and f) rotational solids of profiles a) and b))

The more flat the parabola, the more distant is the focal point (or the focal

plane of the image of the sun) from the apex of the parabola. When compared to

steeper parabola profiles, flat profiles are characterised by a lower ratio of reflec-

tor surface to aperture surface (i.e. effective collector surface). Specific material

consumption is thus reduced. Nevertheless, a certain depth of the profile and con-

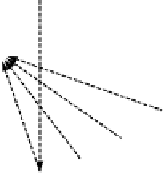

siderable technical effort are inevitable. As an alternative, segmented parabola

profiles - also referred to as Fresnel profiles - are applied. The parabola profile is

subdivided into smaller segments of the same slope at the same point as the pro-

file, but located on the same level. Due to blocking of incident and reflected radia-

tion, reflection efficiencies (i.e. ratio of radiation on aperture surface and concen-

trated radiation) are generally lower than for realised parabola profiles. Fig. 5.3 d)

shows schematic representations of such segmented profiles for extruded profiles

and Fig. 5.3 f) contains a schematic representation of rotational solids.

Rotation profiles present the advantage of generally higher concentration fac-

tors and thus higher process temperatures. However, these concentrators need

two-axis sun-tracking requiring greater technical efforts. Line-focussing systems

only require single-axis tracking and result in lower process temperatures and

efficiencies.

Search WWH ::

Custom Search