Agriculture Reference

In-Depth Information

since all parts are metal. The case may be bronze with stainless steel impel-

lers, or it may be made entirely of bronze.

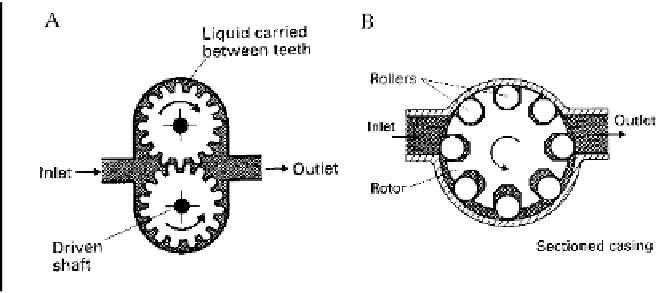

Figure 8.14A

illustrates the gear

pump.

Figure 8.14A and B

Figure A illustrates the gear pump and B the roller

pump.

c.

Diaphragm Pumps

Diaphragm pumps deliver low volume (3 to 10 gpm) at low to moderate

pressure (10 to 100 psi). They withstand abrasion from wettable powder mix-

tures much better than the gear or roller pumps because the spray mixture does

not contact any moving metal parts except the valves. Diaphragm pumps are

positive-displacement, self-priming pumps. The rubber or neoprene diaphragm

may be damaged by some solvents. The pump case is usually iron.

Figure

8.15A

digrams the internal structure of a dighragm pump.

d.

Centrifugal Pumps

Centrifugal pumps are relatively inexpensive pumps adaptable to a wide

variety of spray applications. Generally, they deliver high volume (up to 200

gpm) at low pressures (5 to 70 psi); however, two-stage pumps develop high

pressures (up to 200 psi). Used on agricultural sprayers, commercial spray-dip

machines, and other equipment, these are not positive-displacement pumps, so

pressure regulators and relief valves are not necessary. They are not

self-priming and must be mounted below the tank outlet or with a built-in

priming system. Centrifugal pumps are well adapted for spraying abrasive

materials because the impeller does not contact the pump housing. Slany

models are easily repairable. The pump case is usually iron; the impeller is