Hardware Reference

In-Depth Information

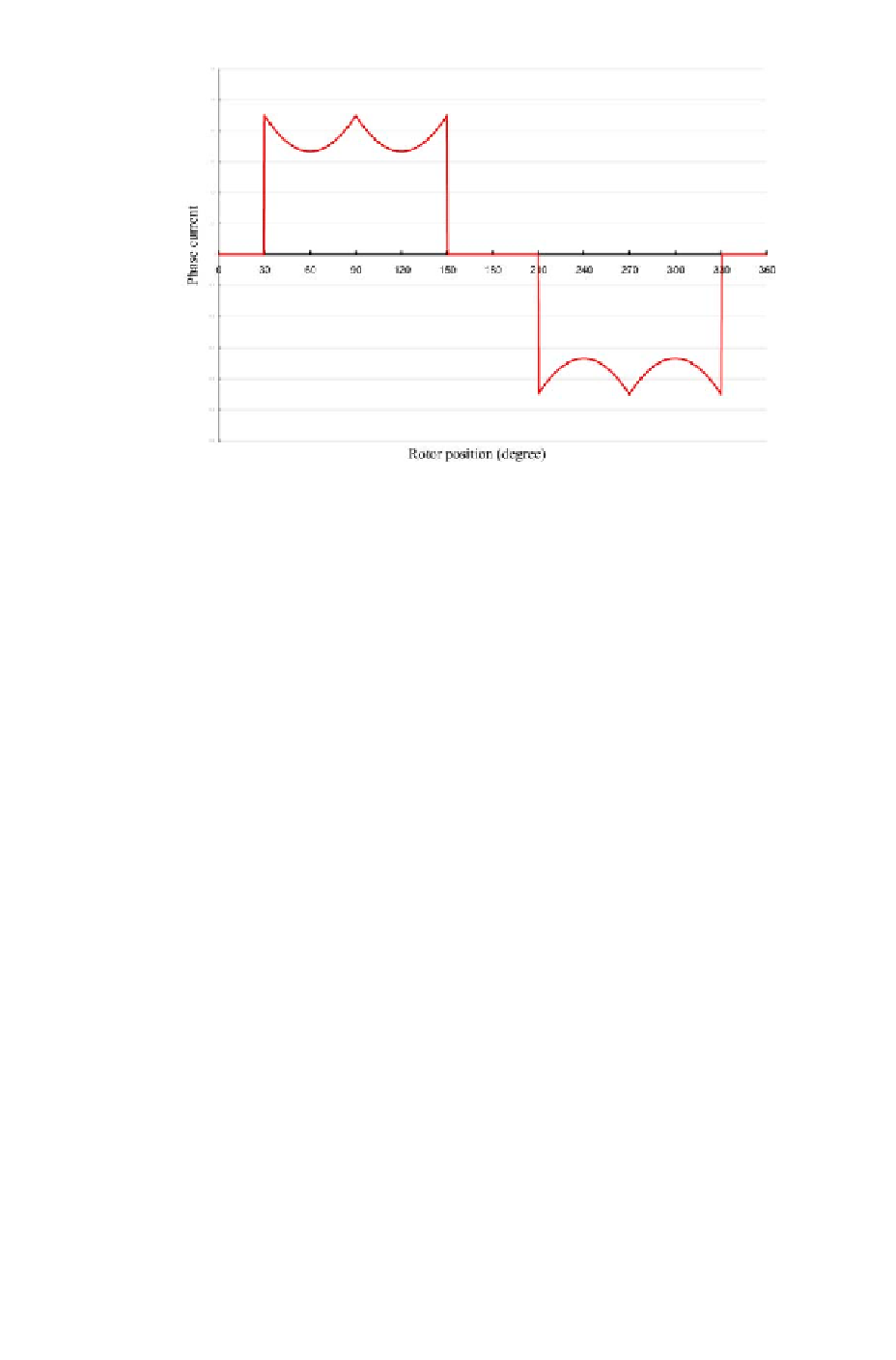

Figure 4.98: The A-phase current waveform produced by optimal commutation

angle with constant voltage drive mode.

4.4.5 Acoustic Noise in Spindle Motor Driven in BLDC

Mode

Many factors can induce acoustic noise in spindle motor operation. The bearing

is the major source of acoustic noise in the spindle motors using ball-bearing.

If

fl

uid dynamic bearings are used, this source of noise is eliminated and the

acoustic performance of the spindle and, therefore, of the HDD is greatly re-

duced. This issue was discussed in section 4.3. Since the noise contributed by

bearings is negligible in FDB spindles, the noise caused by the electromagnetic

sources becomes evident. The magnetic sources of the acoustic noise can be

categorized as

1. the deformation of motor parts caused by the radial

fi

eld [231],

2. unbalanced magnetic pull (UMP) [16], [17], and

3. torque ripples [120], [228].

For PMSM with surfaced PM ring, the airgap magnetic

fi

eld is almost

independent of the drive current (refer to section 4.3.9). Therefore, dependence

of the acoustic noise caused by the deformation of motor parts on the drive

current is insigni

fi

cant. It is not difficult to distinguish this kind of noise during

experiments. The acoustic noise caused by the deformation of spindle motor

parts is very weak [131].

As explained earlier in section 4.3.9, both intrinsic and extrinsic UMPs of

the spindle motor depend on the EM structure of the motor, but they are not