Hardware Reference

In-Depth Information

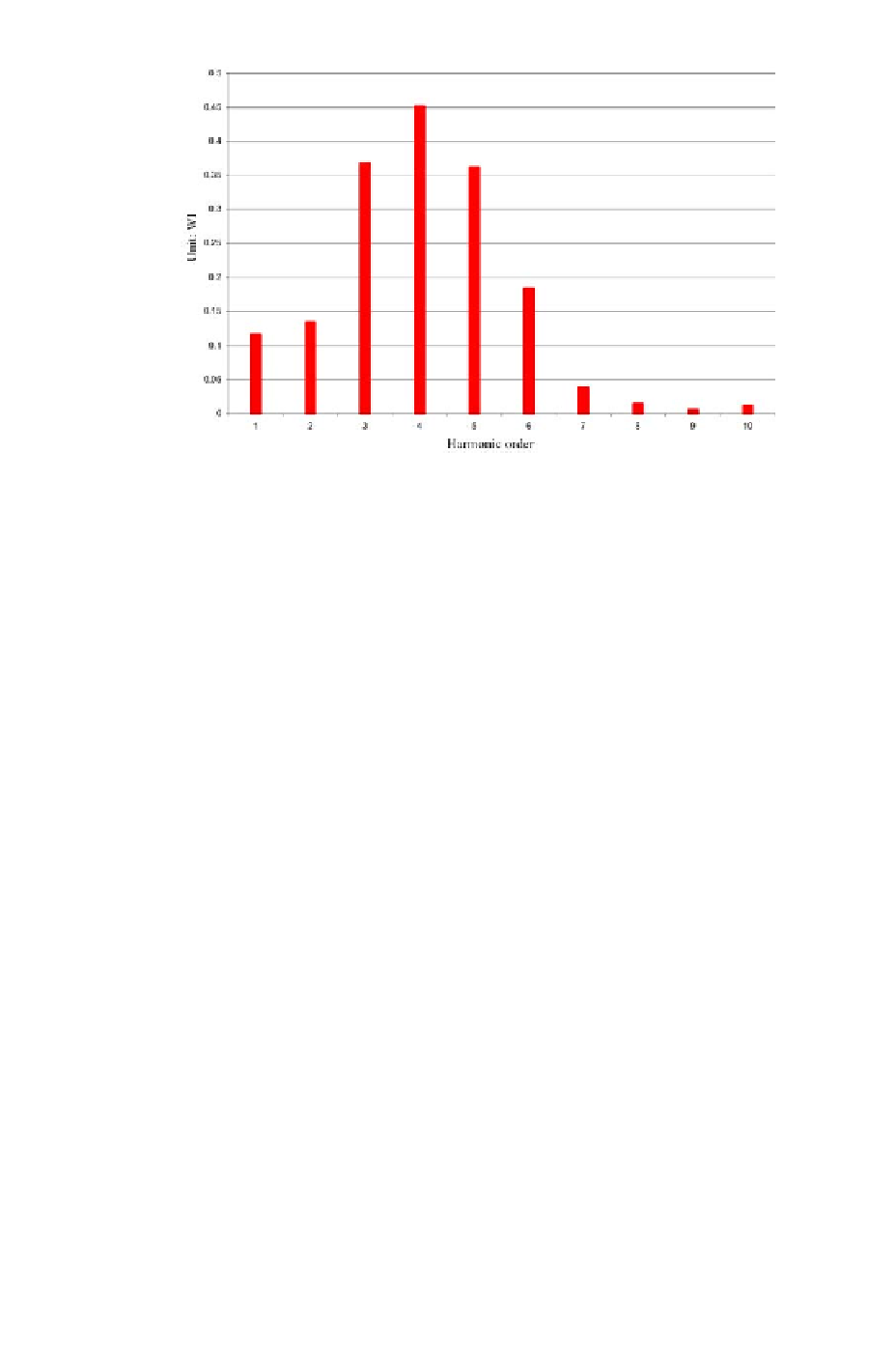

Figure 4.67: The spectrum of the MMF generated by the single phase winding

shown in Figure 4.65.

4.3.9 Cogging Torque, UMP and Armature Reaction

The spindle motor in HDD uses concentrated windings, multiple magnetic

pole-pair and surface-mounted magnet. During the operation of these motors,

cogging torque and UMP are generated which is explained in sections 4.2.3

and 4.2.4.

Bonded NdFeB magnet, surface mounted on the rotor, is used in the HDD

spindle motors. As the relative permeability of the bonded NdFeB magnet

is close to 1, the surface mounted magnet makes the gap length between the

stator core and the rotor core big (see Figure 4.68).

Since the motor core is made of steel, the permeability of each core is much

higher than that of air. The main reluctance in the magnetic circuit of the

motor comes from the airgap between the stator core and the rotor core. This

makes it difficult for the current in the armature to produce strong radial

magnetic

fi

eld in the airgap. Considering that the NdFeB magnet is powerful

in producing the magnetic

fi

eld, the dominant radial airgap

fi

eld is governed

by the magnet. Figure 4.69 shows an example, where, it is found that even

with an armature current 5 times the rated current, the effect on the airgap

radial

fi

eld is insigni

fi

cant.

(1) Cogging torque generated in the spindle motor operation

As the concentrated windings are used and installed in the slots of stator core,

the cogging torque is unavoidable in the spindle motor. Figure 4.70 shows the

cogging torque produced in a spindle motor with 9 slots and 6 pole-pairs.