Hardware Reference

In-Depth Information

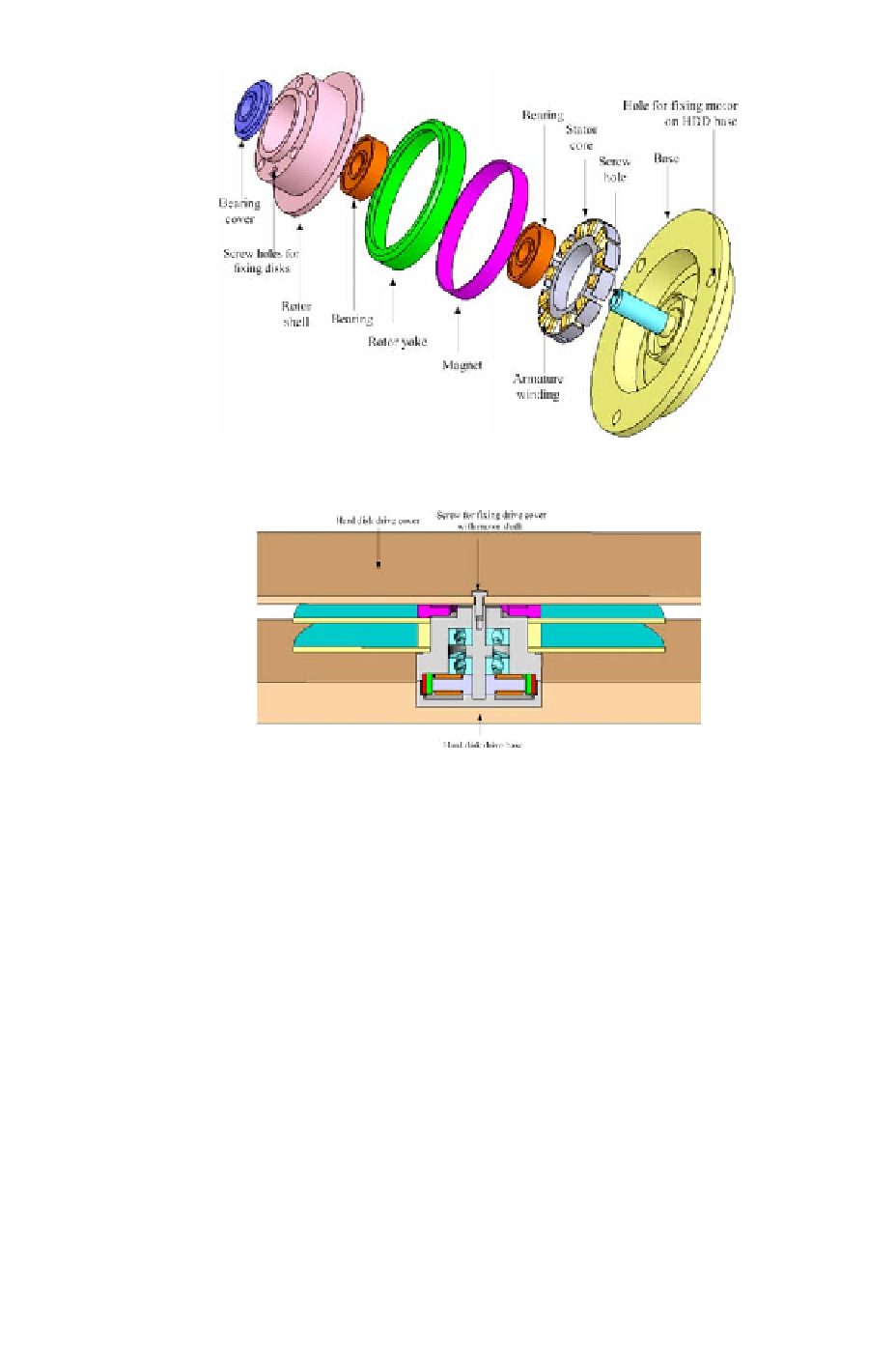

Figure 4.46: Key components of underslung spindle motor.

Figure 4.47: The spindle motor with disks installed inside the drive enclosure.

For this type of motor, one end of the shaft is

fi

xedonthemotorbase

which itself is

fi

xed on the base-plate of HDD. The other end of the shaft can

be screwed onto the HDD cover through a hole on the shaft (Figure 4.47). This

ensures high stiffness for the entire spindle system.

Leakage of lubrication oil from the bearing can contribute to the conta-

mination inside the drive enclosure which is not good for the long life of the

HDD. Contamination from lubrication oil of the bearing is prevented in some

motors using ferro-

fl

uid sealing as shown in Figure 4.48. The ferro-

fl

uid is a

special kind of liquid whose distribution can be changed by applying a mag-

netic

fi

eld. In this type of sealing, the airgap between the rotating parts and

the stationary parts is

fi

lled with ferro-liquid, and a permanent magnet is used

to produce the magnetic

fi

eld to increase viscosity of the

fl

uid. This sealing

prevents leakage of lubrication oil without affecting the spinning of rotor.