Hardware Reference

In-Depth Information

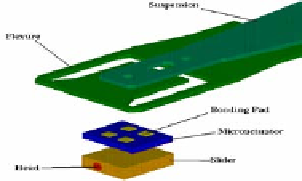

uses a single crystal silicon electrostatic comb drive microactuator mounted be-

tween the slider and suspension. It drives the slider on which a magnetic head

element is attached. Figure 3.66 shows a quarter of the actuator which consists

of a movable rotor connected to an anchored central column via electrical con-

ductive silicon spring beams, and a stator connected to the silicon substrate by

a bus bar which electrically isolates the stator from the rotor. The stator and

rotor of the microactuator are suspended and directly processed from a highly

N-doped single crystal silicon substrate. The dimension of the microactuator

is 1.4 mm × 1.4 mm × 0.18 mm.

Figure 3.65: Schematic of microactuator driving slider.

Figure 3.66: View of one quarter of the microactuator.

The parallel plate pairs attached to the stator and rotor generate electro-

static force. For small rotational angles θ, these plate pairs may be modeled

as parallel plate capacitors separated by gaps. The torque T with a driving

voltage V to half of the structure is given by

µ

¶

2

V

x

n

−Rθ

T ∝ RA

,

(3.140)