Environmental Engineering Reference

In-Depth Information

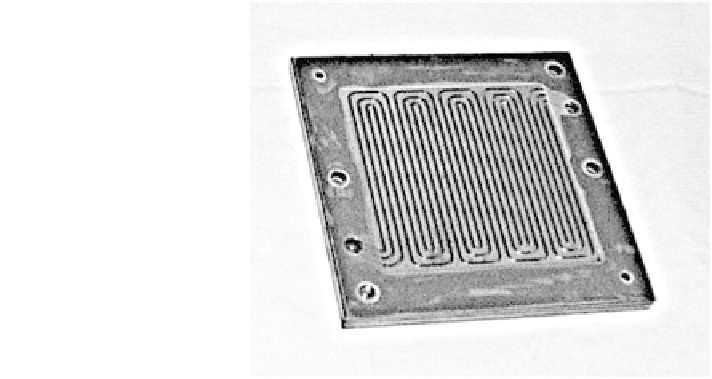

Fig. 3.4 Serpentine gas flow

field in a bipolar plate of a

simple PEM stack

cost, but their high specific weight affects negatively the power density of the

stack, whereas the severe operating environment inside the fuel cell (pH 2-3 and

temperatures of 60-80C) could cause their rapid corrosion, with metal dissolution

and diffusion of metal ions inside the membrane (blocking of sulfonic acid sites)

and consequent reduction of proton conductivity and cell durability. Moreover, a

layer of corroded metal on the plate surface increases its electric resistance and

reduces the output power of the cell. For these reasons the surface of metal plates

is treated with not corrosive and electrically conductive coating layers, such as

conductive polymers, graphite, noble metals, metal carbides, or nitrides.

The lightness and robustness of titanium plate has suggested recent studies

about the possibility to improve its surface properties with the aim of preventing

the formation of passive films (high resistivity oxides), which while would act as

corrosion protectors, could also work as electric insulator increasing the interfacial

contact resistance between the bipolar plate and the GDL, with consequent aug-

ment of the ohmic losses [

42

]. On the other hand, due to the high cost of the pure

metal, as well as of proposed surface modifications (platinum and iridium), tita-

nium could not meet the low-cost requirements typical of the automotive field. In

this view inexpensive metals, such as stainless steel and aluminum, have been

object of major applications. In particular, aluminum has been modified by elec-

troplated nickel alloys, providing materials characterized by the typical robustness

and machining facility of metals, high electric conductivity, and corrosion resis-

tance in the acidic medium of the fuel cell environment [

43

]. Recent researches

have also analyzed the possibility to improve the surface properties of stainless

steel plates, to find a compromise between corrosion resistance and electric con-

ductivity, i.e., between graphite and metal properties, by coating with conductive

amorphous carbon layer [

44

].