Environmental Engineering Reference

In-Depth Information

(but also with carbon dioxide) to produce carbon monoxide and hydrogen,

according to the following equation that is the reverse of Eq.

2.8

C

þ

H

2

OCO

þ

H

2

DH

¼þ

131 kJ/mol

ð

2

:

18

Þ

In addition, the reversible gas phase water gas shift reaction (

2.3

) reaches very

fast equilibrium at temperatures typical of a gasifier. The above chemical equa-

tions balance all the product (CO, CO

2

,H

2

O, H

2

) concentrations of the process.

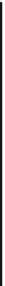

Gasification process could be inserted in a Integrated Gasification Combined

Cycle plant (IGCC) [

54

,

55

] to improve the overall process efficiency. The syngas

produced in the gasifier is used as fuel in the gas turbine generator of the integrated

combined-cycle technology, which consists also of a heat recovery steam gener-

ator and a steam turbine/generator. A simplified scheme of a proposed gasification

overall plant for generation of both electricity and hydrogen is reported in Fig.

2.3

.

The scheme evidences different steps to produce electricity and hydrogen. The

heart of the overall process remains the gasifier. The coal fed to the reactor is

Sulfur By-Product

CO, CO

2

, H

2

Shift

Reactor

1000 - 1500

°C

H2

Solid By-product

Coal

Air

Air

Combustor

Compressor - Expander

Steam

Air

Gas Turbine

S

te

a

m Gen

e

rat

o

r

Solid By-Product

Electric Power

Electric Power

Steam Turbine

Fig. 2.3

Simplified scheme of an integrated gasification plant [

54

]