Environmental Engineering Reference

In-Depth Information

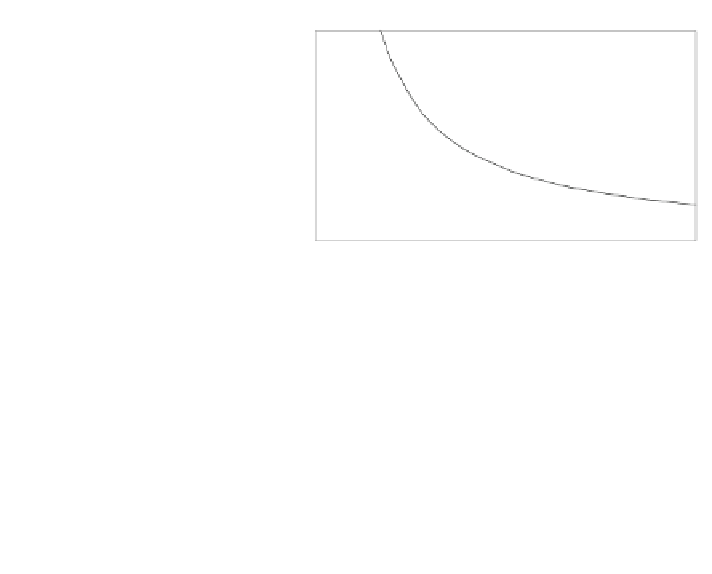

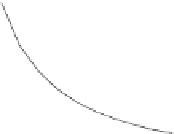

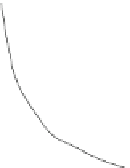

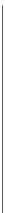

Fig. 7.40 a Stoichiometric

ratio versus stack current for

four different management

strategies. b Air flow rate

versus stack current for the

management strategies (a)

a

12

law 1 (Qair 33 m3/h)

law 2 (Qair 24 m3/h)

law 3

law 4

10

8

6

4

2

0

0

40

80

120

160

200

Stack Current , A

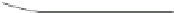

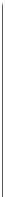

b

35

30

25

20

15

law n.1

law n.2

law n.3

law n.4

10

5

0

0

20

40

60

80 100 120 140 160 180 200

Stack Current, A

from 1.5 to 2 V (60 A as stack current), then after a constant phase at 2 V the

voltage reference is linearly increased up to 4 V in the range 110-200 A of the

stack current. This last management strategy allows the compressor consumption

to be minimized with R values such as to guarantee a regular stack operation in

steady state operations.

The study of the effects of compressor management strategy on the efficiencies

of stack and subsystem (SC) composed by stack and compressor is preliminarily

carried out in steady state conditions. In particular, the stack efficiency (g

stack

)is

calculated by using the Eq.

7.1

starting from the data obtained at 313 K with the

compressor management curve 4 (Fig.

7.40

a, b) and reported in Fig.

7.41

as

function of stack current. A linear trend can be observed in the range 30-200 A

corresponding to an efficiency decrease from 0.7 to 0.5. The g

stack

curves for the

other management strategies are not reported because they are not significantly

affected by R [ 2. In Fig.

7.41

, g

SC

(Eq.

7.3

) is also reported for all the different

compressor management strategies of Fig.

7.40

a.

Differently from stack efficiency the g

SC

values are clearly dependent on the

profile of R utilized, due to compressor consumptions connected to different motor

speed regulations. In particular, highest g

SC

values decrease from 0.60 to 0.53

passing from management curve 4 to 1, with major differences in the field of lower

loads (under 100 A).