Environmental Engineering Reference

In-Depth Information

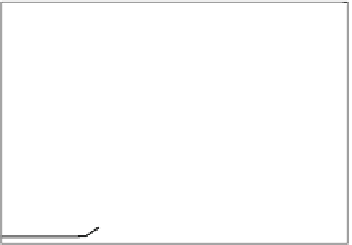

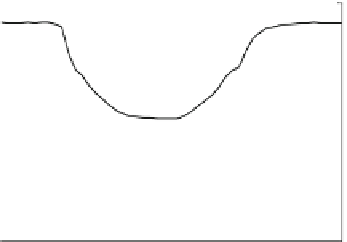

Fig. 7.19 Stack voltage and

current versus time for a

dynamic test at 50 A s

-1

80

500

70

Stack Voltage

Stack Current

400

60

50

300

40

200

30

100

20

0

10

0

5

10

15

20

25

Time [s]

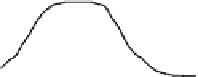

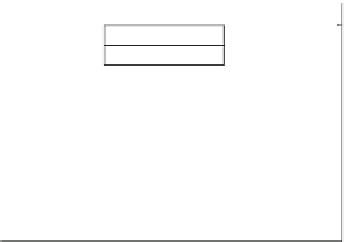

Fig. 7.20 Stoichiometric

ratio and air flow rate versus

time for the experiment of

Fig.

7.19

80

3

70

2.5

60

2

50

Stoichiometric Ratio

Air Flow Rate

1.5

40

1

30

0.5

20

10

0

0

5

10

15

20

25

Time [s]

together with the total stack voltage. This voltage drops down from 71 to about

45 V at the end of the acceleration step, then remains constant during the sta-

tionary phase (5 s), and rise again during the deceleration step. The R and air flow

rate profiles, reported in Fig.

7.20

, evidences that the compressor operation is

stressed by the high dynamic adopted, in particular the faster dynamic of this test

determines an appreciable effect on the stoichiometric ratio, whose profile

decreases below 1.5 at the end of the acceleration phase. This behavior is further

evidenced in Figs.

7.21

and

7.22

, where the individual cell voltages are plotted as

function of cycle length and as histogram acquired at the instant corresponding to

the highest current peak, respectively. A problem of stack malfunctioning is

clearly evidenced for several cells, in particular the first one dropped under 0.3 V,

while the other three cells among the last 20 did not reached 0.4 V. The reason for

this behavior is attributed to difficulties of the air compressor in supplying the right

values of stoichiometric ratio (Fig.

7.20

), and this suggests to change the air

compressor strategy in order to increase R values during the fastest dynamic

phases. Figures

7.23

,

7.24

,

7.25

, and

7.26

show the results of a test on the R40

cycle operating at 50 A s

-1

during the acceleration phases, but modified regarding

the maximum power, which is limited to the optimal power obtainable by the stack